What’s a Pick List? Definition, Examples, and Key Benefits

If you’ve ever shipped the wrong product—or missed an item in a rush—you know how costly warehouse picking mistakes can be. It’s frustrating for your team and your customers. And these common problems cost time, money, and customer trust.

Today, warehouse operations need to be faster and more accurate than ever. Customers expect speed, and businesses can’t afford delays or returns due to simple, avoidable errors. That’s why having a clear, reliable pick list system matters.

Pick lists are important tools for any business handling physical inventory. In this guide, we’ll break down what a pick list is, how it fits into your workflow, and how the right software can make it all a lot easier.

What is a Pick List?

A pick list (sometimes called a picking list) is a document that tells your warehouse staff exactly which items to “pick” from your inventory to fulfill customer orders. Think of it as a shopping list for your warehouse workers that guides them through the picking process.

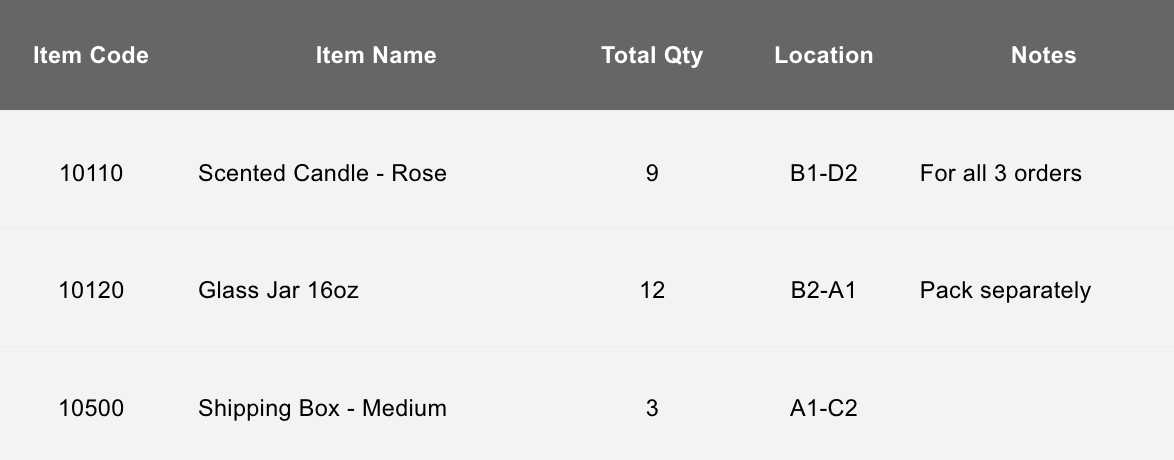

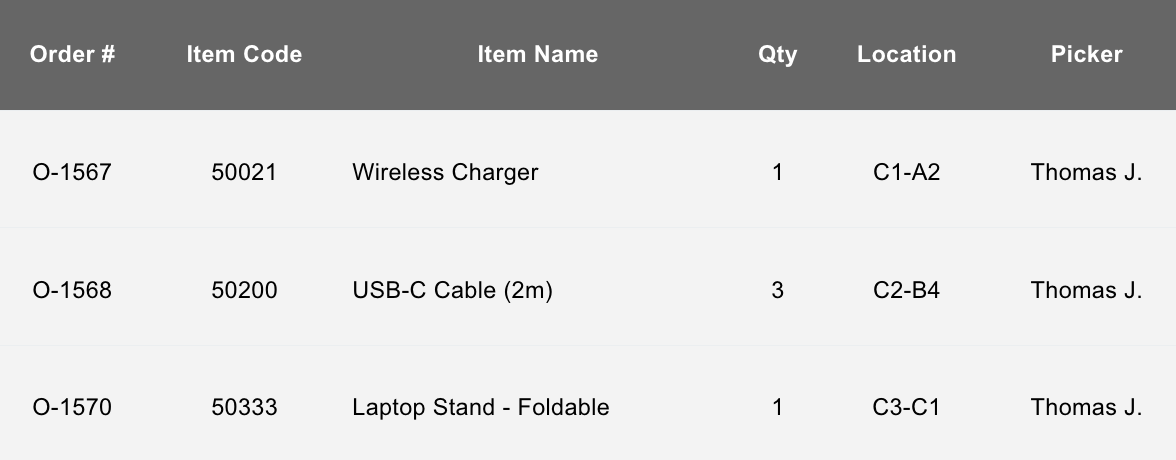

Pick lists usually include:

• Quantities needed

• Storage locations (aisle, shelf, bin)

• The order or customer the items are for

• Special handling notes (like “fragile” or “keep refrigerated”)

• Suggested picking route or sequence

You might start with paper or by creating a pick list in Excel, but most growing businesses quickly switch to digital tools. Modern pick list software can generate lists automatically and send them straight to your pickers—no printing required.

Key Benefits of a Good Pick List in Warehousing

A good pick list system does more than keep things organized—it helps your warehouse run better in every way:

- Fewer Mistakes: When your team knows exactly what to pick, errors drop.

- Faster Picking: Organized picking routes save time, especially in large warehouses.

- Real-Time Tracking: When your pick list updates warehouse inventory automatically, stock counts stay accurate.

- Repeat Customers: When orders go out quickly and correctly, customers come back.

- Lower Labor Costs: You can fulfill more orders with fewer pickers.

- Room to Grow: As your order volume increases, your pick list system scales with you.

- On-The-Go Mobile Access: Pick lists can be managed through a mobile app, so your team can work from anywhere in the warehouse.

With the right tool, you experience faster fulfillment and fewer returns just by switching to an automated pick list system.

Different Types of Pick Lists: What Works Best?

Not every warehouse picks the same way. Your pick list strategy should match your business size, layout, and order volume. Here are the most common types:

▶︎ Single-Order Pick List

Picks one order at a time. Best for small businesses with low order volume or businesses that handle custom, high-value items.

▶︎ Batch Pick List

Picks items for several orders at once. Reduces walking time by combining multiple orders into a single picking session.

Batch ID: #BATCH-305

Date: May 29, 2025

Orders Included: #O-1043, #O-1044, #O-1045

▶︎ Zone Pick List

Best for large warehouses with distinct product sections or special storage requirements. Assigns specific zones of the warehouse to individual pickers.

▶︎ Wave Pick List

Sends out picking instructions in scheduled periods (or “waves”) to match shipping times.

Wave Time: 10:00 AM

Wave ID: #WAVE-05

Shipping Target: Same-Day Dispatch

▶︎ Cluster Pick List

Combines multiple orders and sorts picked items into customer-specific bins.

How to Create an Effective Pick List System

A reliable pick list system is all about clarity and consistency.

1. Start with a Customer Order

It all begins when a customer places an order. From there, your system should automatically create a pick list—or you can generate one manually if needed. Generate the List

Build a clear list that includes:

• Product name and description (including size, color, etc.)

• Quantity to pick

• Where it’s stored in your warehouse

2. Use Location Codes

Precise location codes speed up the picking process. A typical location format might include:

• Bay or zone

• Shelf

• Bin

For example: A4-B2-S3-12 = Aisle 4, Bay 2, Shelf 3, Bin 12.

3. Plan Smart Picking Routes

Order your list based on how someone would move through your warehouse. That means grouping items by aisle and location to avoid unnecessary backtracking.

4. Add Verification Steps

Help your team double-check their work with:

• Barcode scanning with digital tools

• Fields to confirm picked quantities

5. Implement Quality Control

Add a checkpoint to catch errors before packing:

- Weigh items when needed

- Take photos of expensive items

- Have supervisors do spot checks

6. Handle Special Items Carefully

Make sure your pick list flags anything that needs extra care:

• Temperature-sensitive products

• Age-restricted products

• Items that need special packaging

How to Choose the Right Pick List Software Solution

If your team is juggling spreadsheets, printing pick lists, or manually updating every order, it might be time to upgrade. Here’s how to tell you need an upgrade:

- You’re getting more returns due to wrong picks

- Orders are delayed because pickers can’t find items

- Your inventory doesn’t match what’s in your system

- Multiple team members need access to lists at once

Great pick list software should do more than just list items—it should help you pick smarter and faster. Look for tools that offer:

- Real-time inventory updates – So stock levels adjust the moment something is picked

- Barcode scanning– To make sure the right item gets picked every time

- Mobile access – Allows your team to pull up pick lists right on their phone or tablet

- Route optimization – Suggests the fastest path through the warehouse

- Integrations – Syncs with your e-commerce, shipping, and accounting tools

- User permissions – So you control who can edit or access pick lists

- Reports and analytics – To track how fast and accurately your team is working

- Custom templates – Adjust layouts to match your picking style

- Cloud-based access – Work from anywhere, on any device

Common Pick List Challenges (and How to Solve Them)

Even with a solid system, things don’t always go smoothly. Here’s how to tackle some of the most common pick list issues:

▶︎ Items Not Where They Should Be

Run regular cycle counts to keep your inventory locations accurate. A quick audit every other week helps catch errors before they slow down your pickers.

▶︎ Stockouts During Picking

Use real-time inventory tracking and low stock alerts so you can restock before something runs out. It’s one of the easiest ways to prevent fulfillment delays.

▶︎ Managing Pick List Changes

Digital pick lists are key here. When things change—like an item swap or a canceled order, updates show up instantly, keeping everyone on the same page.

▶︎ Scaling as You Grow

Choose a pick list system that’s flexible and scalable. As you add more products or locations, it should let you bring new team members on board and manage permissions easily.

▶︎ Team Communication

Centralized access to the same live data helps eliminate back-and-forth between warehouse workers, sales, and management. Everyone knows what’s going on without long email chains.

▶︎ Handling Returns

A good system makes it easy to guide returns back to the right spot and updates your stock levels automatically.

▶︎ Accuracy Issues

Scanning barcodes during picking helps you maintain stock accuracy. It ensures what’s picked is exactly what was ordered, reducing mistakes.

Getting Started: Your Pick List Plan

Ready to improve how your warehouse runs and finally get your picking process under control? Here’s a simple step-by-step plan to help you launch a digital pick list system—without overwhelming your team.

1. Assess Your Current Needs

Start by looking at how things are working today.

- Are pickers spending too much time looking for items?

- Are shipping mistakes causing returns?

Pinpoint the biggest issues so you know where to focus first.

2. Set Up Your Account

Choose a tool that’s easy to get started with—something that won’t require weeks of onboarding. Look for options that offer a free trial period so you can explore their features and see if they’re the right fit. Setup is quick, and you can begin by adding your products.

3. Organize Your Warehouse

Before any software can help, your physical space needs to be organized. Label everything clearly, group frequently ordered items together, and logically lay out your zones. A warehouse space management feature can help you map and maintain that structure over time.

4. Import Your Inventory

Now, bring your product data into the system. You can do this manually, through a spreadsheet upload, or by syncing with your online store. Don’t forget to include:

• Current stock levels

• Warehouse locations

• Any special handling instructions

5. Train Your Team

Even with an easy-to-use system, a little guidance goes a long way. Walk your team through the process, explain why the changes matter, and provide some quick reference docs or videos. Many platforms offer tutorials to help with onboarding if you need extra support.

6. Start with a Pilot

Rather than overhauling everything at once, try the new system on a small group of products or a few daily orders. This helps you spot any issues early and gives your team time to adjust.

7. Measure Your Results

Once you're up and running, track the impact of the new system:

• Are orders going out faster?

• Are returns decreasing?

• How does your team feel about the new process?

Final Thoughts

A good pick list software is more than a checklist—it’s the backbone of your fulfillment process. It helps you stay accurate, flexible, and ready to scale.

If you're still relying on printed spreadsheets or manually updating inventory, now’s a great time to make a change. With the right pick list system, you can cut down on mistakes, ship faster, and make life easier for your team.

BoxHero makes it easy to get started with all aspects of inventory management. Try it out for free and see how it can support your daily operations.

RELATED POSTS