How to Simplify Your Order Management Process

Order management is a critical component of any product-based business, but it can quickly become complex if not handled effectively. Order management encompasses the entire process from when a customer places an order to when they receive their purchase - and sometimes even beyond.

When executed well, it keeps your operations running smoothly and ensures customer satisfaction. However, inefficient order management can lead to dissatisfied customers, lost revenue, and increased stress for you and your team.

In this article, we'll examine common challenges you might face in order management and provide practical strategies to simplify your process using technology.

What is Order Management?

Order management is the process of receiving, tracking, and fulfilling customer orders. It's the bridge between your sales and your inventory, ensuring that customers get what they ordered, when they expect it.

Why Order Management Matters

Effective order management is crucial for several reasons:

- Customer satisfaction: Timely and accurate order fulfillment keeps customers happy and encourages repeat business.

- Operational efficiency: Streamlined processes reduce costs and save time.

- Inventory control: Proper order management helps maintain optimal stock levels.

- Financial health: It impacts cash flow and profitability by ensuring timely payments and reducing errors.

The Ripple Effect

Think of order management as the pebble in the pond of your business operations. When it's working well, it creates positive ripples across your entire organization:

- Sales team: Can confidently make promises to customers about delivery times.

- Warehouse staff: Know exactly what needs to be picked, packed, and shipped.

- Finance department: Can accurately forecast cash flow based on pending orders.

Common Challenges in Order Management

Even with the best intentions, businesses often encounter hurdles in their order management process. Let's explore some of the most frequent issues you might face and how they can impact your business.

(A) Order Processing Delays

Nothing frustrates customers more than waiting too long for their orders. Processing delays can occur due to various factors, with manual data entry being a significant culprit.

Imagine your sales team receiving orders via phone or email and then manually typing each into your system. This slows down the process and introduces the risk of human error. A simple typo in a product code or quantity can lead to significant problems down the line.

Inefficient workflows can also cause delays. If your sales team, warehouse staff, and shipping department aren't in sync, orders can get stuck in limbo. For example, your sales representative takes an order, but the information doesn't reach the warehouse promptly. The delay in picking and packing the order could push back the shipping date, leading to a disappointed customer.

Lack of real-time inventory data is another common issue. You might accept an order for an item you believe is in stock, only to discover later that it's out of stock. This leads to backorders, delayed shipments, and potentially lost sales if customers cancel their orders out of frustration.

(B) Fulfillment Errors

Mistakes happen, but in order fulfillment, they can be costly. One of the most common errors is picking the wrong items. For example, if you sell different sizes or colors of the same product, it's easy for warehouse staff to grab the wrong one, especially if your inventory isn't well-organized.

Shipping to the wrong address is another frequent issue. This often happens when orders are manually entered, and a digit in the address is mistyped. The result? Your product ends up at the wrong destination, leading to a frustrated customer and additional shipping costs for your business.

Quantity errors can also occur, particularly with bulk orders. For example, your customer orders 100 units but receives only 10. Not only does this disappoint the customer, but it also creates additional work for your team to correct the error and may impact your inventory counts.

(C) Inefficient Order Tracking

In today's connected world, customers expect to know where their order is at all times. If your system doesn't update in real time, you can't provide accurate information to inquiring customers. It leads to a poor customer experience and could result in lost future sales.

Disconnected systems pose another challenge. If your order management system doesn't communicate with your shipping partners, tracking becomes a manual and time-consuming process. Your team might spend hours each day checking tracking numbers on carrier websites and manually updating your system, time that could be better spent on other tasks.

(D) The Inventory Balancing Act — Stockouts & Overstocks

Maintaining the right inventory levels is crucial but challenging. Stockouts can lead to lost sales and disappointed customers. Without real-time inventory tracking, you might not realize you're out of stock until it's too late, leading to backorders or canceled sales.

On the flip side, overstocking ties up capital in excess inventory and can strain your finances. You might order too much of a product that doesn't sell as well as anticipated, leaving you with warehouse space filled with slow-moving items and less cash available for other business needs.

These challenges are common, but they're not unbeatable. Recognizing them is the first step toward improving your order management process and growing your business more efficiently.

You can overcome these hurdles with the right strategies and tools and create a smoother, more effective order management system.

Key Steps in the Order Management Process

Understanding the core components of order management can help you identify areas for improvement in your own business. Let's walk through the key steps of an effective order management process.

1. Receiving Inventory from Suppliers

The journey begins even before a customer places an order. Efficient order management starts with a well-organized system for receiving inventory from your suppliers. This involves:

- Accurately counting and inspecting incoming goods

- Updating your inventory management system with new stock levels

- Storing items in designated locations for easy retrieval

For example, when a shipment of new products arrives, your team should have a clear process for checking that the correct items and quantities have been delivered, promptly entering this information into your system, and storing the products in a logical, easy-to-find manner.

2. Storing and Organizing Inventory

Once you've received your inventory, proper storage is crucial. This step is about more than just finding space for your products. It's about organizing them in a way that facilitates quick and accurate order fulfillment.

Consider implementing a system like bin locations or barcode scanning. This can dramatically reduce the time it takes to locate items and decrease errors in picking. This way, your warehouse staff can go directly to the exact shelf and bin where an item is stored rather than searching multiple areas.

3. Receiving Customer Orders

When a customer places an order through your website, over the phone, or in person, this information must be captured accurately and efficiently. Modern order management systems can automatically import orders from various sales channels, reducing manual data entry and the associated risks of errors.

For instance, when a customer places an order on your e-commerce site, it should automatically appear in your order management system, triggering the fulfillment process without any manual intervention.

4. Preparing and Packing Ordered Items

Once an order is received, it's time for picking and packing. This step involves:

- Locating the ordered items in your warehouse

- Picking the correct quantities

- Packing items securely for shipping

Efficiency here is key. The faster and more accurately you can pick and pack orders, the quicker you can ship them out, and the happier your customers will be. Many businesses use picking lists or mobile devices to guide warehouse staff through this process, ensuring accuracy and speed.

5. Shipping the Orders

The final step in the physical process is shipping the packed orders to your customers. This involves:

- Selecting the appropriate shipping method based on customer preference and order details

- Generating shipping labels

- Updating order status and providing tracking information to the customer

An effective order management system can automate much of this process, selecting the best shipping method based on predefined rules, automatically generating labels, and updating the order status.

6. Post-Shipment Follow-Up

While the physical journey of the product ends with shipping, the order management process doesn't stop there. Following up with customers to ensure they receive their orders and are satisfied is an often overlooked but crucial step. This can be as simple as an automated email asking for feedback or as thorough as a personal phone call for high-value orders.

7. Handling Returns and Exchanges

This step is crucial for maintaining customer satisfaction and trust. Efficiently managing returns and exchanges can turn a potentially negative customer experience into a positive one.

For instance, a clear and simple returns policy, along with a clear process for accepting returns can help ensure customer satisfaction and encourage repeat business. Implementing a system that handles returns with the same efficiency as order processing can help maintain the integrity of your inventory and keep your customers happy.

While not a direct part of the physical handling of orders, providing excellent customer support, including answering queries about products, order status updates, and handling any issues that arise post-purchase, is essential.

This ongoing support helps build long-term customer relationships, enhancing their overall experience with your brand.

3 Tips to Simplify Order Management

Managing orders doesn't have to be a constant struggle. Here are three key strategies you can implement to improve your process and boost efficiency.

1. Automate Order Processes

Investing in automation can transform the way you handle orders. By reducing manual tasks, you can save time, minimize errors, and free up your team to focus on more valuable activities.

Start by identifying repetitive tasks in your order process. For instance, data entry is a common time sink. Instead of manually inputting each order, look for ways to automate this process. Many e-commerce platforms can integrate directly with inventory management systems, allowing orders to flow automatically into your system as soon as a customer clicks "buy."

Automation isn't just about the initial order capture. Look for opportunities to automate throughout the process, from inventory updates to shipping label creation and even customer notifications.

2. Improve Communication and Collaboration

Clear communication between your sales, inventory, and fulfillment teams is vital for smooth order management. When these departments operate in silos, it often leads to mistakes and delays.

- Implement a centralized system where all teams can access real-time information about orders and inventory. This transparency allows everyone to work from the same, up-to-date information. For example, if your sales team can see current inventory levels, they can set accurate expectations with customers about product availability and shipping times.

- Consider using collaborative tools that allow team members to leave notes or updates on specific orders. This can be particularly helpful for complex orders or when some changes or issues need to be communicated across departments.

3. Optimize Inventory Management

Effective inventory management is the backbone of smooth order fulfillment. Knowing exactly what you have in stock and where each item is located allows you to process orders more quickly and accurately.

Regularly conduct cycle counts to maintain accurate inventory records and use your order management system to set reorder points for each product, ensuring you never run out of popular items.

Don't forget about demand forecasting. Use your sales data to predict future demand and adjust your inventory accordingly. This can help you avoid both stockouts and overstocking, optimizing your inventory investment.

Example: Implement a system of bin locations or barcodes in your warehouse. This can dramatically speed up the picking process and reduce errors, as your team will know exactly where to find each item without unnecessary searching.

All-in-one Solution: Using Inventory Management Software

Now, you might be wondering how to put all these ideas and strategies into action. The answer lies in using the right tools, specifically inventory management software with robust order management capabilities.

Why Choose Inventory Management Software?

Inventory management software offers a centralized platform to handle all aspects of your order process. Here's how it addresses the key areas we've discussed:

- Automation: One of the primary advantages of inventory management software is its ability to automate repetitive tasks. From importing orders to updating inventory levels, automation reduces manual data entry and the associated risk of human errors.

- Real-time Inventory Sync: With up-to-date inventory information at your fingertips, you can prevent stockouts and overstocking. This real-time data ensures you can confidently accept orders and provide accurate delivery estimates to customers.

- Order Tracking and Updates: Modern inventory systems offer comprehensive order tracking, allowing you to monitor the status of each order from placement to delivery. Many also provide automatic updates to customers, improving transparency and reducing customer service inquiries.

BoxHero, a leading inventory management solution, offers a powerful

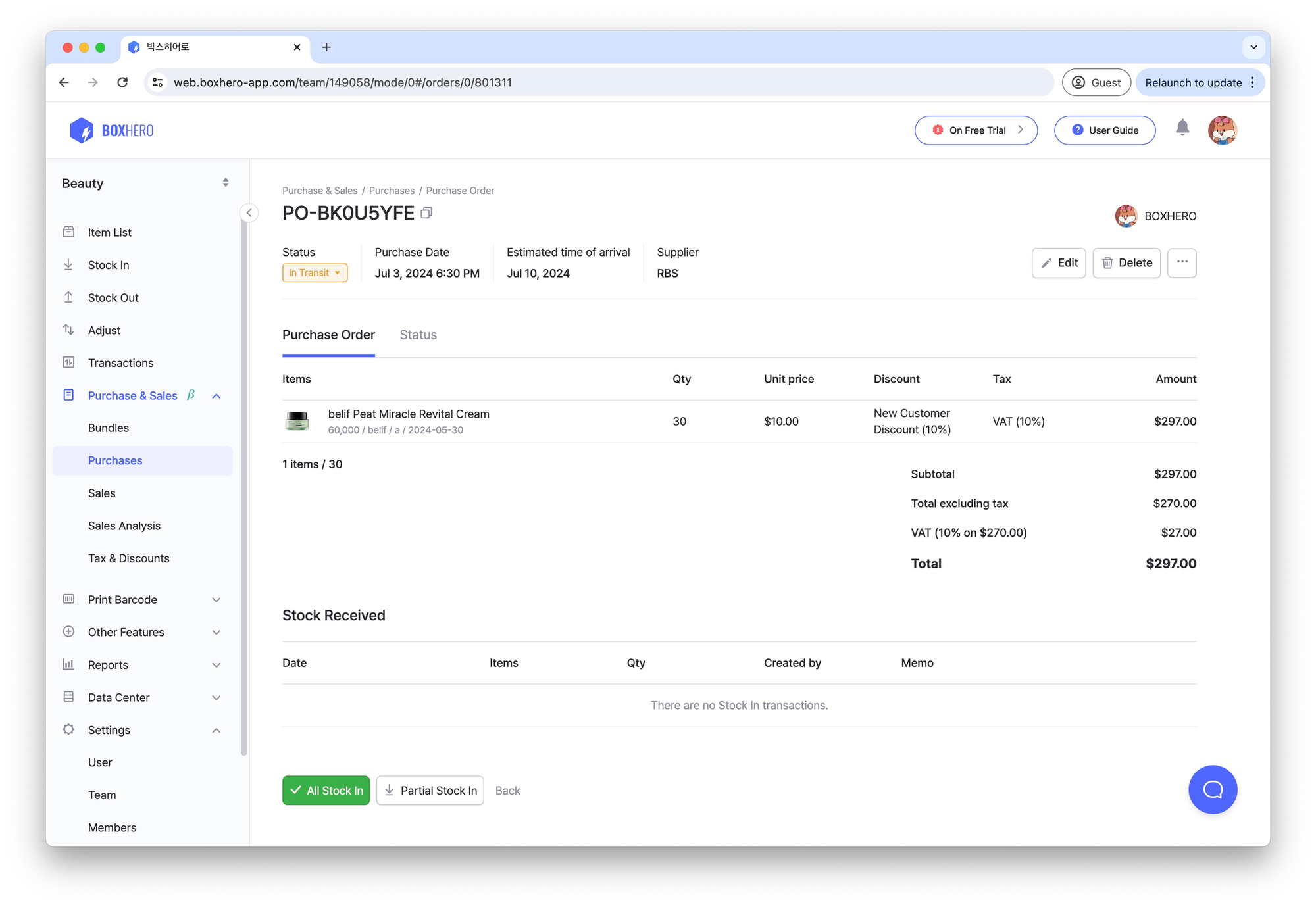

Purchases & Sales function to simplify your order management process. Let's explore how this feature can benefit your business:Comprehensive Order Management

BoxHero's Purchases & Sales function allows you to manage both your purchase orders (from suppliers) and sales orders (to customers) within the same system. This integration provides a holistic view of your supply chain and order fulfillment process.

For example, when you create a sales order in BoxHero, the system will automatically check your current inventory levels to ensure you can fulfill the order. If stock levels are low, it provides tools like the Low Stock Alert feature. This feature sends a notification to your phone, alerting you when an item is running low. This timely alert helps you take proactive steps, such as creating a purchase order to replenish stock, ensuring you can consistently meet customer demand without interruption.

Simplified Invoicing

Generate professional invoices for both purchases and sales directly within BoxHero. This feature eliminates the need for separate invoicing software, centralizing your financial documentation and making tracking payments and managing cash flow easier.

Real-time Sales Analysis

BoxHero's Purchases & Sales function goes beyond basic order tracking. It provides real-time sales analysis, allowing you to identify your best-selling products, track revenue trends, and make data-driven decisions about inventory management and purchasing.

You can quickly identify which products are flying off the shelves and which are slow movers. This insight can help you optimize your inventory levels and focus your marketing efforts on high-performing items.

Mobile Accessibility

With BoxHero's mobile app, you can manage orders on the go. Whether you're in the warehouse, at a supplier meeting, or working remotely, you have full access to your order and inventory data.

This mobile functionality is particularly useful for businesses with multiple locations or those that frequently work outside the office. You can check stock levels, create orders, or review sales data from anywhere, at any time.

Streamlined Orders, Happy Customers

Effective order management is essential for the success of any product-based business. However, common challenges like processing delays, fulfillment errors, and inventory imbalances can quickly derail your operations and frustrate customers.

By implementing inventory management software like BoxHero, you can simplify your order processes and overcome these hurdles. From reducing manual data entry to providing real-time inventory updates, this powerful tool can help you refine your operations, improve accuracy, and ultimately enhance customer satisfaction.