Using Predictive Logistics to Sharpen Your Inventory Forecasting

One of the hardest parts of running a small to medium-sized business (SMB) is aligning inventory planning with logistics. Whether it’s trade wars, natural disasters or shifting customer demands, SMBs are challenged to operate efficiently in the face of so much uncertainty. The right technology, however, can help you overcome these obstacles and sharpen inventory forecasting so that you’re prepared, no matter what.

If you’re looking to take your inventory and logistics planning to the next level, keep reading. We’ll break down predictive logistics, why they matter to SMBs, and how they can benefit inventory management and so much more. We’ll also provide an easy roadmap on how to integrate the technology for the best results.

What is Predictive Logistics?

Predictive logistics uses AI-powered algorithms to analyze data and forecast supply chain disruptions and events. By providing business leaders with a forward-looking analysis of probable future events, predictive analytics empowers them to make better decisions.

By analyzing past information, predictive logistics platforms can pick up demand trends, common routing issues, etc., so that those experiences become a guide on how to improve future strategies.

In addition, predictive logistics can include external information such as seasonal, market, and weather trends for a broader, more robust perspective. For example, predictive analytics can help flag when a business’s products are most in demand during the year and if there’s a correlation to weather events.

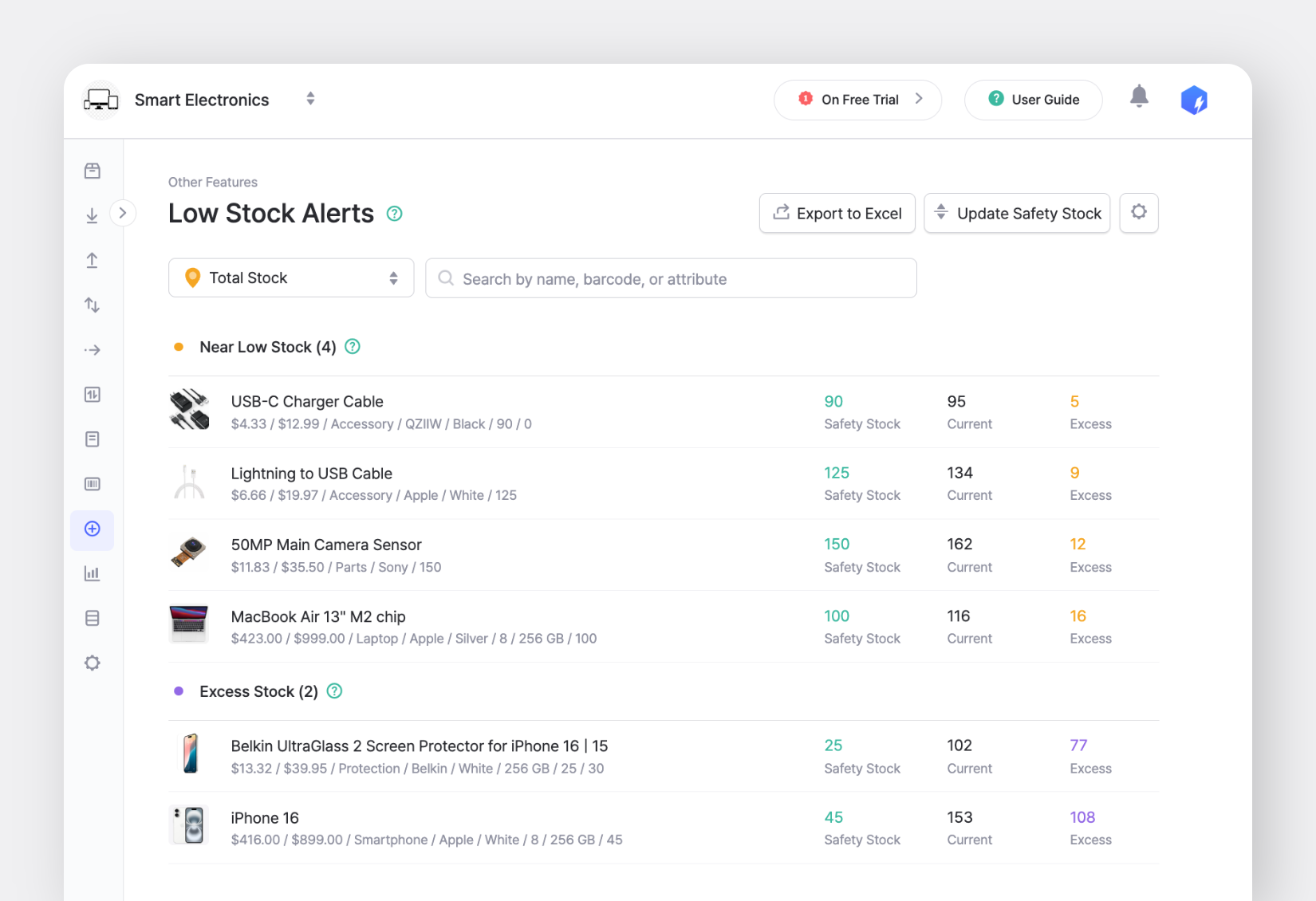

That in itself makes inventory planning so much easier and more accurate. Many of these platforms also include options for automated alerts to flag potential signs of logistics and inventory issues such as low stock or inadequate transport.

Retailers who have piloted predictive logistics tools have seen a 12-20% drop in redundant stock and major improvements in their fulfillment efficiency.

Why Predictive Logistics Matters for SMBs

Though predictive logistics has historically been used primarily by enterprise-level companies, SMBs can benefit from using the technology as well. Not only can it help smaller businesses better compete against peers, but it gives you a shot at taking on the powerhouses too.

As anyone managing inventory knows, even the smallest error can land a business with cash flow problems, angry customers, and stunted growth. That’s why predictive logistics is so important. It can help track over-ordering and avoid overspending, as well as ensure that the products your customers want are always in stock.

Being able to better serve customers has a positive effect on overall growth and is often the thing that allows SMBs to scale up. By helping to anticipate what inventory will be needed and when, predictive logistics gives SMBs a major competitive edge.

How Predictive Logistics Sharpens Inventory Forecasting

Predictive logistics provide a data-driven approach to inventory forecasting that can be used to optimize nearly every aspect of your supply chain. They’re able to do this by analyzing:

- Your sales history and any purchasing patterns.

- Holidays, weather trends, and other seasonal factors that may affect the above.

- Past and future trends in consumer behavior and your overall industry.

- Upcoming economic changes.

- Supplier reliability and average lead times from them.

Together, all these data points provide clear insights into when it’s best to order inventory or hold off. There’s no guessing involved. Just precise data and actionable information that sharpens your inventory management strategy so that your business can flourish.

Connecting Inventory and Freight for End-to-End Visibility

Combining predictive logistics with the inventory management capabilities means that businesses get to track not just what they have in stock, but where it is and what’s on its way. In short, you get end-to-end supply chain visibility.

The value of this is huge.

So often, inventory errors happen because teams don’t have a clear picture of what’s out for delivery or which goods are still coming in from suppliers. For example, a common misstep is placing inventory orders too late and then ending up with an accidental stock-out. Connecting to freight tracking and predictive platforms helps prevent this. They give an accurate view of delivery timelines so that businesses have more control of what’s coming in and out of their warehouses.

Here's an example of a Transportation Management System (TMS) by Sheer Logistics, a leading provider in logistics and supply‑chain services:

They can also send out alerts for unusually long supplier lead times or potential routing issues that might slow delivery. This gives businesses a chance to seek backup options and keep their inventory numbers under control, even when things change.

Most predictive freight platforms provide dashboards with real-time data that allow businesses to track exactly when goods are arriving or when their own deliveries will make it to their destinations. All of this makes inventory planning so much more accurate and effective.

Key Benefits: Less Waste, More Control, Happier Customers

The best way to sum up the impact that predictive logistics can have on SMBs is by looking at the key practical benefits the technology can bring:

- Fewer Rush Orders: Rush orders are usually the result of poor or inaccurate planning. Predictive logistics gives you all the information you need to plan better and anticipate potential obstacles long before they arrive. This alone helps ensure that last-minute orders become a thing of the past.

- Lower Holding Costs: Storage costs can eat into an SMB’s budget. The AI-powered forecasting that predictive logistics tools provide can reduce inventory levels by 20 to 30%.

- Why? The technology helps predict inventory demand so that you only hold of the stock you know you can sell.

- Why? The technology helps predict inventory demand so that you only hold of the stock you know you can sell.

- Less Inventory Waste: An added benefit of more accurate inventory management is waste reduction. This is particularly relevant to SMBs dealing with products that can spoil.

- Better Cash Flow Management: Less waste and less risk of overstocking also add up to better cash flow management. It helps businesses direct their money where it’s truly needed and avoid overspending.

- Balance Supply and Demand: Balancing inventory levels so that you have enough when customers come knocking but not so much that it ends up gathering dust can seem like an impossible guessing game. Predictive logistics takes that stress away by forecasting upcoming trends that businesses can then strategize their inventory planning around.

- More Control and Agility: Control and flexibility might sound like opposing concepts, but they’re two sides of the same supply chain coin. Predictive logistics gives businesses more control over their data and their future, which in turn allows them to respond more quickly to any shifts or disruptions.

- Better Customer Experiences: The one market trend that doesn’t seem to be shifting is the customer desire for quick turnarounds. Serving that interest is so much easier when inventory management and forecasting are in place. You’re able to anticipate your customers’ needs more easily and in turn, create positive experiences that keep them coming back for more.

- Build A Business That Can Grow: Predictive logistics can scale easily with a business and help support inventory needs as they grow. By embracing this technology, SMBs set themselves up to be able to expand their reach without having to worry as much about overextending their capacity.

Getting Started: A Simple Roadmap to Smarter Inventory

Connecting inventory management with predictive logistics opens a world of possibilities. Here’s how you can harness both areas for smarter inventory and greater success:

Get Control of Your Inventory Data

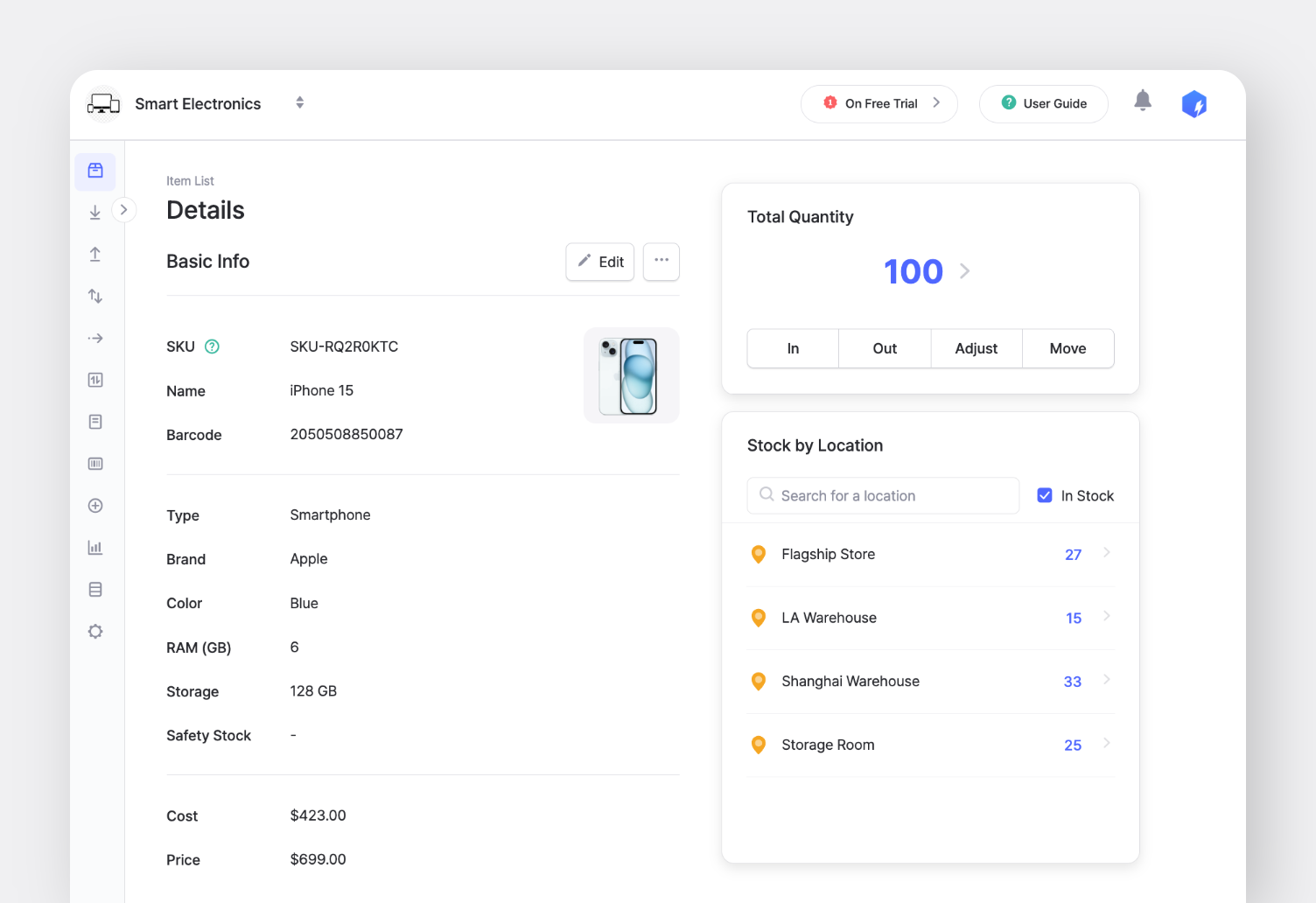

Inventory management platforms like BoxHero are designed to help SMBs digitize and track inventory in real-time. It’s the first step to gaining control over your data and being able to generate insights from it.

Define Your Forecasting Needs

Every business has slightly different concerns. Get to grips with what you need forecasted and then build your usage of the tools around that for the most impactful results. This will also help prevent teams from getting overwhelmed in the early stages.

Integrate Predictive Logistics

Logistics service providers offer transportation management systems (TMS) and predictive tools that can take all the data collected by your inventory management platform and turn that into demand forecasting, supplier performance stats, and insights on how to plan routing better.

Advance with Automation

Even just doing the above will help scale operations, but to advance even further, businesses need to implement automation. Look for an inventory management platform that allows you to automate reorders and integrate with your logistics service provider and TMS.

Automatically tracking supplier lead times and potential delays means fewer unforeseen emergencies and more time for businesses to focus on building their impact, connecting with customers, and chasing their goals.

Wrapping Up

For many small businesses, keeping inventory in check while juggling logistics can be overwhelming. Predictive logistics helps take some of the pressure off by avoiding stockouts, cutting back on storage costs, or just knowing what to expect next week.

With a solid inventory system and reliable logistics insights, it becomes a lot easier to make decisions, avoid last-minute scrambles, and keep things moving. You’ll spend less time putting out fires and more time focusing on what actually moves your business forward.