How to Optimize Your Inventory

Looking for a better way to manage your inventory?

If you’re new to inventory or want a clearer approach, this guide will help. We’ll cover why inventory matters, a simple metric to watch, and three practical steps you can use today.

Why It Matters

Picture your favorite ice cream shop. 🍦

Chocolate is the best-seller and your favorite. If it’s sold out every time you stop by, you’ll leave disappointed — even if plenty of other flavors are available. That’s what customers feel when the item they want is out of stock. Repeated shortages hurt your reputation and make shoppers more likely to go elsewhere next time.

Running out of items doesn’t just lose a sale in the moment. It damages trust and makes future purchases less likely. On the other side, holding too many items ties up cash and creates storage headaches.

The aim is to keep enough on hand to meet demand without letting inventory sit unused. The key is optimizing your inventory.

What is Inventory Optimization?

Although the phrase ‘inventory optimization’ may seem like a grandiose process, it is actually about getting to know your inventory better.

There are a variety of processes to help you start optimizing your inventory. One process starts with checking your inventory management process. If there is a large number of quantities frequently missing at the end of the month, it may be a sign that your team needs to implement an inventory audit regularly.

Another method would be to start calculating your inventory turnover rate. 📊

- Inventory Turnover= COGS / Average Inventory

- COGS = Cost of Goods Sold

- Average Inventory = (Beginning Inventory + Ending Inventory) / 2

If the number is too high, it might be due to either your business doing well or ordering too few products per cycle. If the number is too low, you may want to consider ordering less and conduct clearance sales for items that are stuck in storage.

Let us get a closer look at inventory optimization.

3 Ways to Optimize your Inventory

1. Categorize Your Inventory

If your clothes were rambled together in a big pile, it would take a long time to find the piece you want. So in most households, clothes are organized in hangers or drawers by their category. This form of categorization actually works well with inventorying.

When registering your products in a list, make sure to insert categories as well. Categories help to sort and filter your products in a group and increase the visibility of your inventory.

2. Barcode Your Products

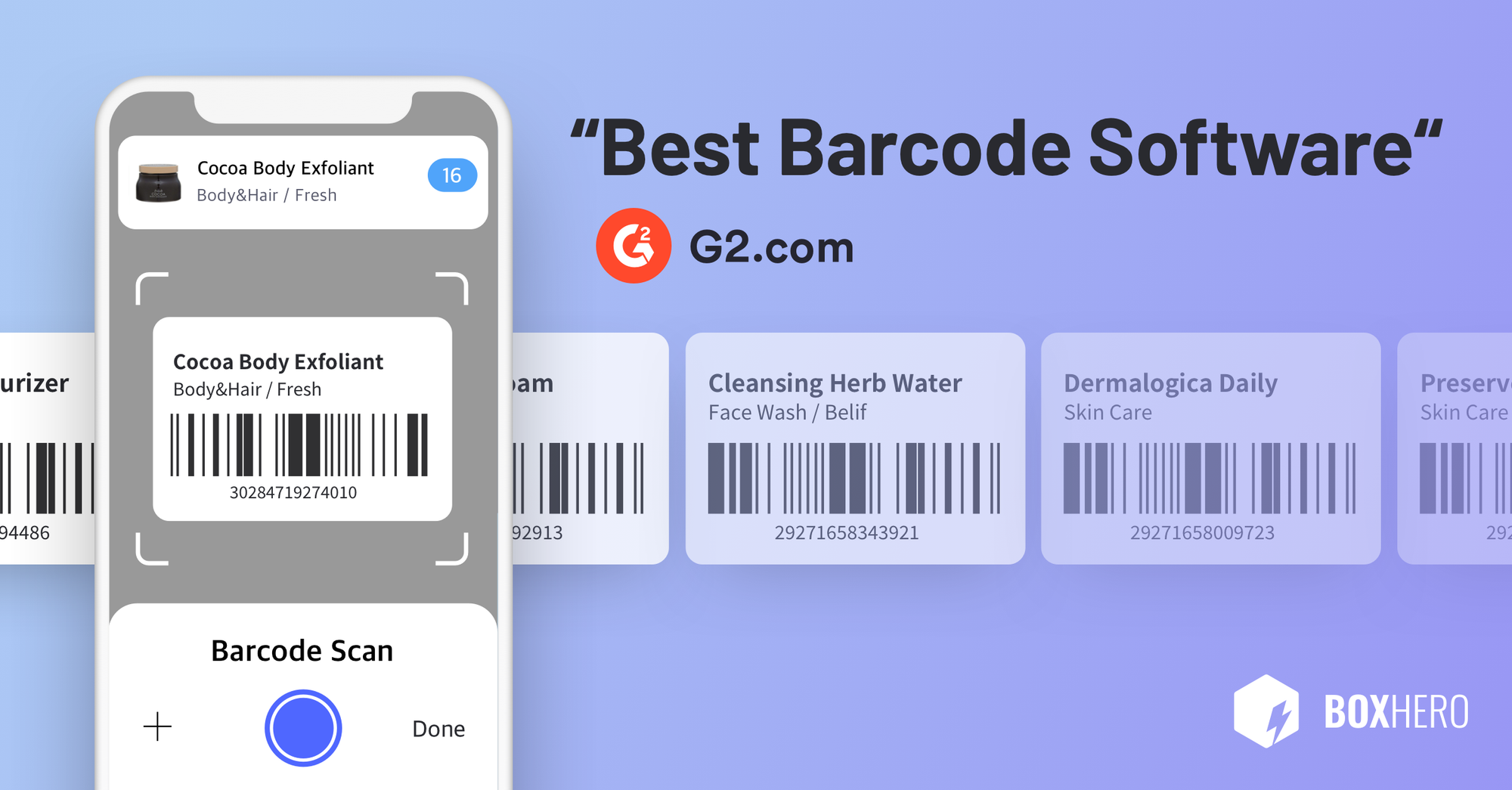

Even if your products do not have a barcode, it does not mean you do not need one. Barcode not only acts as a unique identifier for your product, but it also helps minimize your time searching for the product. With the help of a barcode scanner, not only is checking the product status easier, but also conducting an inventory count becomes less troublesome.

3. Use a Cloud-based, Real-time Inventory Software

With cloud-based, real-time inventory software, not only is your inventory data secured but also all team members are able to check current inventory updates simultaneously. Especially with stock control software provided in both desktop web and mobile app versions, it helps to manage whenever, wherever and greatly increases inventory accuracy.

Ready to Try It?

Optimizing inventory doesn’t require a big project.

Start with one change: add categories, barcode a fast-moving item, or try a cloud app for your next count. Small steps lead to fewer stockouts and less dead inventory.

Looking for software to try? BoxHero makes tracking items, barcodes, and real-time counts simple for businesses of any size.