Inventory Management Glossary: 50 Terms Every Entrepreneur Should Know

Managing your inventory means knowing the language that goes with it. A shared vocabulary can keep your team aligned, cut down on mix-ups, and helps you avoid ordering mistakes.

This “Inventory Management Glossary” lays out 50 essential terms with clear definitions and real examples. Use it to set reorder points you can trust, uncover hidden carrying costs, and keep customers happy with on-time deliveries.

With these 50 terms and you’ll be able to:

- Spot issues early, before they turn into stockouts or write-offs

- Have clearer conversations with suppliers and your team

- Decide how much to order and when, using real demand data

A – L

1. ABC Analysis

A method for classifying items by value: “A” items (high value), “B” items (moderate), “C” items (low). More specifically:

- A (20% of items that represent 80% of value)

- B (30% of items worth 15%)

- C (50% of items worth 5%)

Use case: A small electronics retailer reviews sales data monthly and orders A-items weekly, B-items biweekly, and C-items quarterly. By focusing their effort where it counts most, they were able to save 25% on ordering fees.

2. Aging Report

A report showing how long each item has been in stock. It lists how many days each item has sat on the shelf, and is helpful for spotting slow-moving or obsolete items.

Use case: A food supplier flags batches older than 60 days and offers discounts to clear them before spoilage.

Example:

Tyson Grilled Chicken Strips (Frozen) 6×22 oz

- Received: May 10, 2025 | Days on hand: 92 | Cases: 14

- Lot: TY-0510 | Best by: Apr 30, 2026

- Action: 10% discount at slow-turn accounts; bundle with frozen veggies.

- Goal: Improve turns without margin loss.

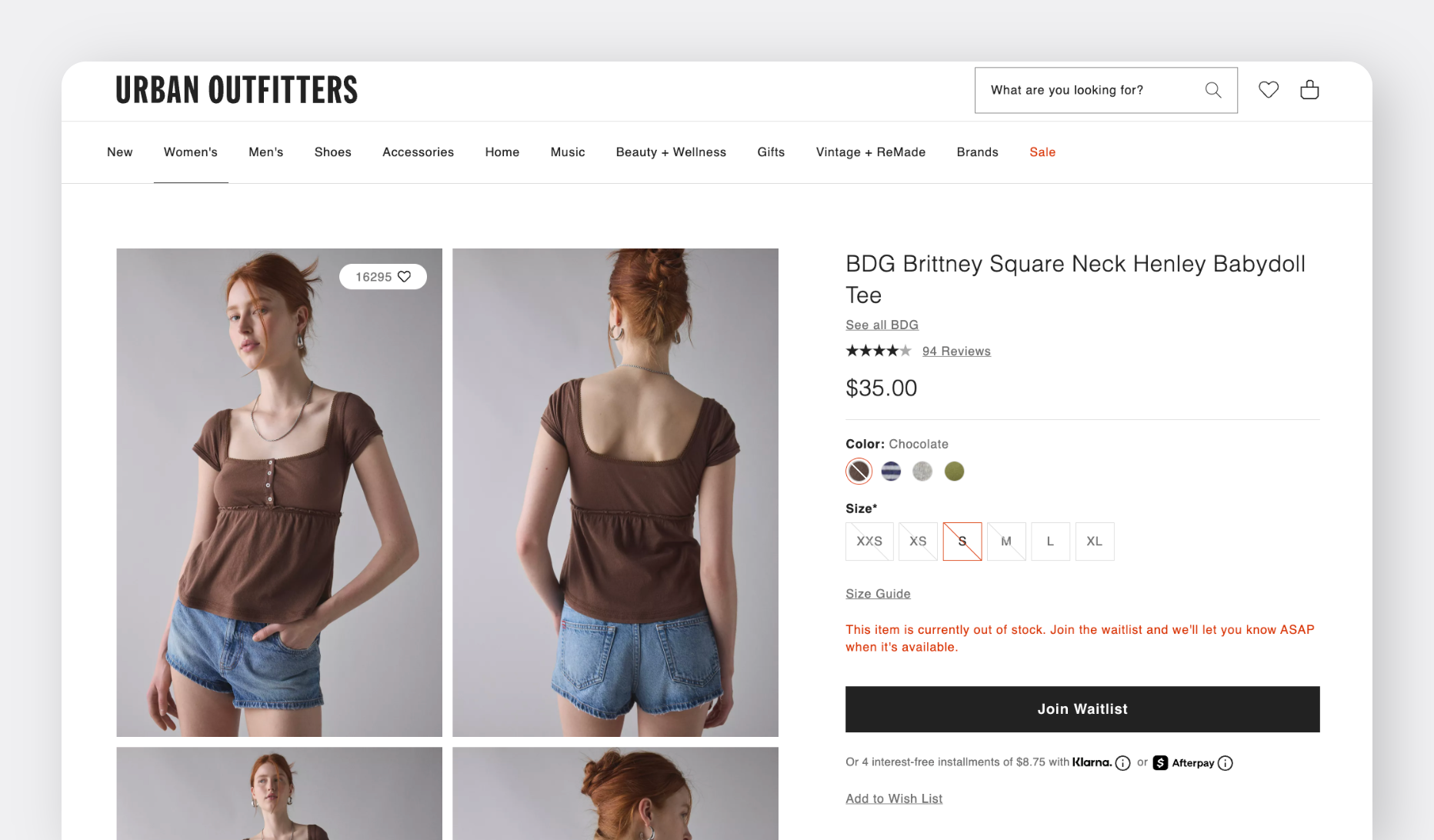

3. Backorder

An order you can’t fill right away due to no on-hand stock. When you can’t fill an order from existing stock, the order becomes a backorder until new items arrive.

Use case: When a fashion boutique sells out of a popular shirt, they email customers with an expected ship date (and sometimes offer a small gift for the delay).

4. Batch Tracking

Assigning a unique identifier to a group of items produced together, so you can trace quality issues like defects or recalls back to their source.

Use case: A cosmetics brand tracks every lipstick batch; when a crumbly batch is reported, they locate and replace only that lot.

5. Bill of Materials (BOM)

A detailed list of all components needed to assemble a finished good. A BOM is especially useful for manufacturers and kit-based sellers.

Use case: A small electronics manufacturer assembles a smart thermostat. The BOM lists 1 main PCB, 1 LCD, 1 housing set, 4 screws, and 1 wiring harness so purchasing orders the right parts and assembly can verify each unit before pack-out.

6. Bin Location

The exact shelf or bin ID where an item lives in your warehouse or storage area. Knowing this precise spot can speed up picking and packing.

Use case: An e-commerce center labels hard drives in aisle B, rack 3, bin 14, and employees pick 40% faster than before.

7. Carrying Cost

The total cost of holding items in storage such as rent, insurance, utilities, spoilage, etc. Expressed as a percentage of inventory value, it typically amounts to 20–30% of value per year.

Example point: If you store $100,000 of goods and carrying cost (holding cost) is 25%, you pay $25,000 a year just to keep them on shelves. 💰

8. Consignment Inventory

Stock stored at your location but owned by the supplier until you actually sell it. With consignment inventory, you can reduces upfront costs and risk.

Use case: A bike shop carries expensive e-bikes without upfront payment; the supplier only bills when a bike goes out the door.

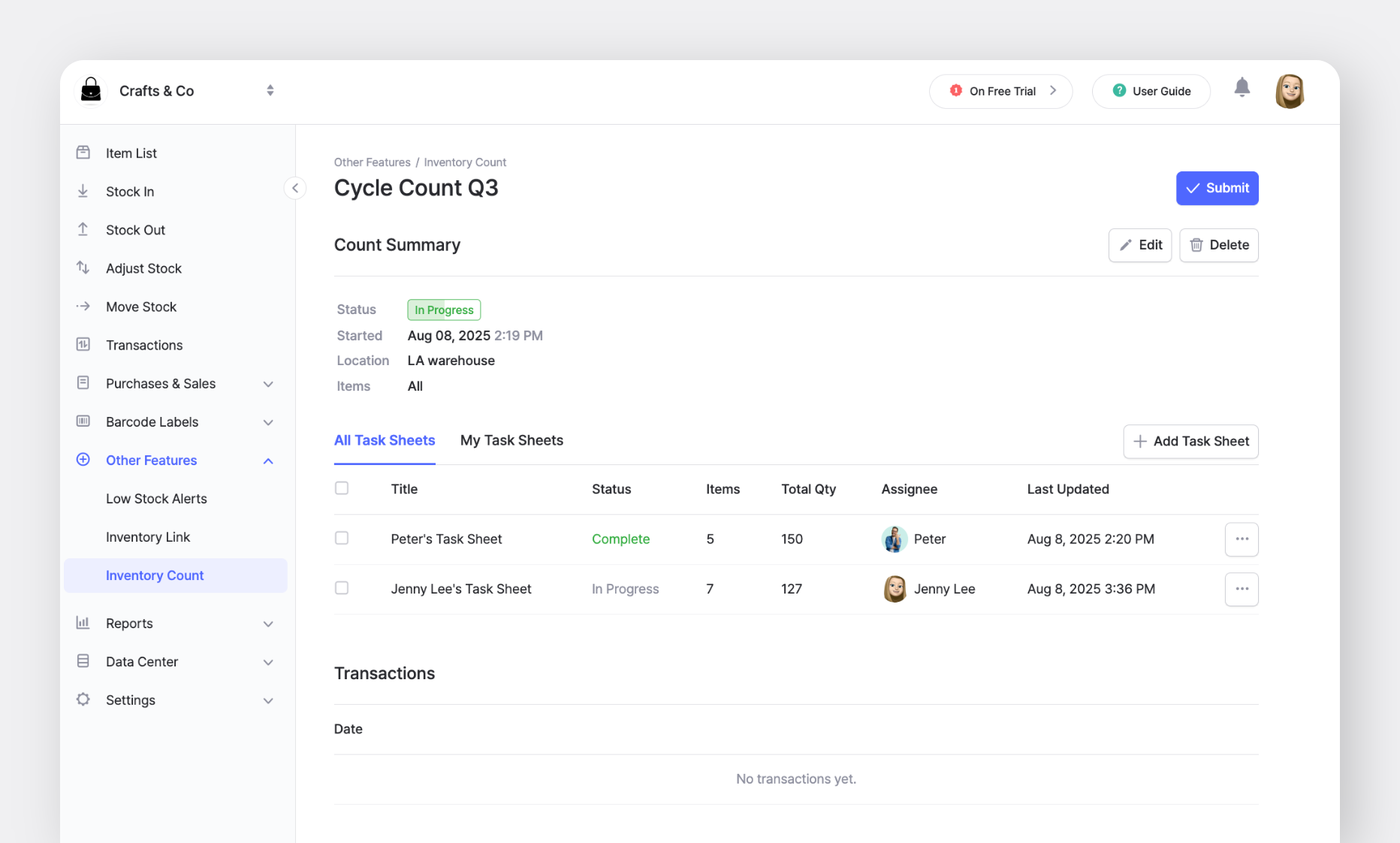

9. Cycle Count

A regular, partial count of inventory that checks accuracy without shutting down operations for a full stocktake. You count a subset of SKUs on a schedule and fix variances quickly.

Use case: A home-goods warehouse counts high-value items every week and lower-value items monthly to maintain 99% accuracy with minimal disruption.

• ABC method: A items often weekly, B monthly, C quarterly.

• Location method: One aisle or bay per day.

• Event-based: Count after big receipts, promotions, or process changes.

10. Days of Inventory on Hand (DOH)

How many days current stock will last at your expected sales rate.

Formula: DOH = On-hand units ÷ Average daily demand

Example point: You have 600 units on hand and sell 30 per day.

DOH = 600 ÷ 30 = 20 days. With a 14-day lead time and 3 safety days, you should plan to reorder as DOH nears 17–20.

11. Demand Forecasting

Predicting future item demand based on sales history, seasonality, and market signals. Using these trends helps you avoid stockouts and overstock.

Use case: A swimwear brand sees spikes in May and June. Using last year’s sales and waitlist signals, they increase orders in March to hit peak season without stockouts.

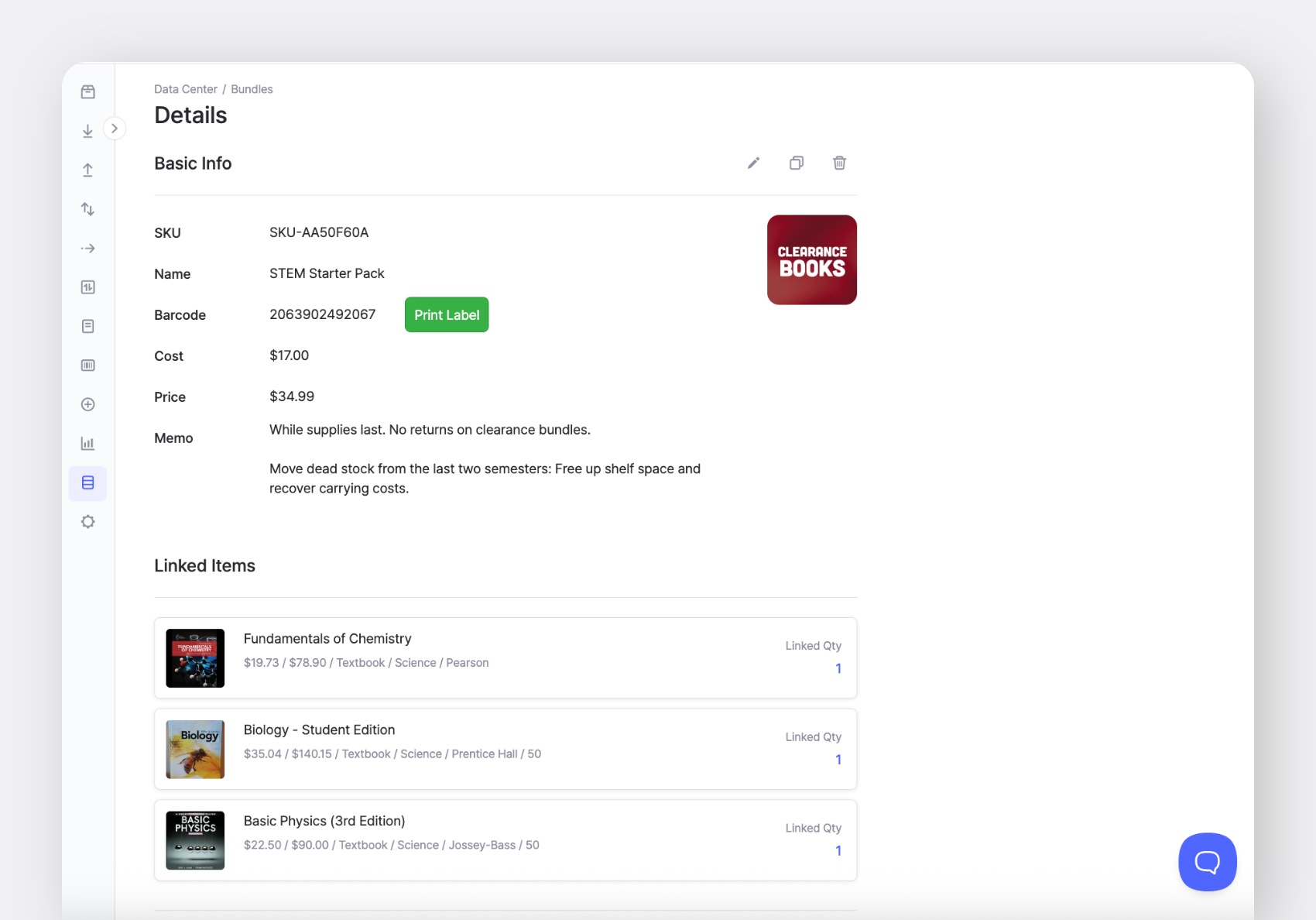

12. Dead Stock

Items that haven’t sold in a long time and are unlikely to move. They tie up cash and shelf space, so it's best to discount or bundle them and clear room for items that do sell.

Use case: A bookstore marks outdated textbooks as dead stock after two semesters and bundles them for clearance sales.

• Set an aging threshold (e.g., 120 days without a sale).

• Run targeted discounts or bundles to recover cash.

• Remove dead stock from reorders.

• Replace them with faster-moving variants.

13. Dropshipping

An order fulfillment model where you pass orders directly to a supplier, who ships items straight to your customer. You list and market the item, send the paid order to the supplier, then pay the wholesale cost after the customer pays. You never handle the inventory.

Use case: A home décor startup tests new product lines via dropshipping. It involves no upfront inventory risk, which lets them try seasonal or bulky items without a big buy.

14. Economic Order Quantity (EOQ)

The ideal reorder quantity that minimizes total ordering and carrying (holding) costs.

Formula: EOQ = √((2 × D × S) / H), where:

- D = annual demand (units)

- S = cost per order (admin, freight, receiving)

- H = annual holding cost per unit (storage, risk of obsolescence)

Example point: If your EOQ calculator shows 500 units, you avoid ordering 100 units too often (high fees) or 1,000 units too rarely (high carrying costs).

15. Fill Rate

The percentage (%) of customer orders you can fulfill immediately from on-hand inventory.

Use case: A supplement retailer measures fill rate daily; when it dipped below 95%, they added a reorder point review.

16. First-in, First-out (FIFO)

You sell or use the oldest items first, reducing spoilage and obsolescence. FIFO is common in food and beverage, cosmetics, chemicals, and any item with a shelf life.

Use case: A bakery sells cupcakes baked yesterday before today’s batch, which cuts waste and keeps freshness consistent.

I – P

17. Inventory Turnover

A ratio showing how many times you sell and replace your entire stock in a set period (usually a year).

Formula:

Turnover = Cost of Goods Sold (COGS) ÷ Average Inventory

where Avg. Inventory = (Beginning Inventory + Ending Inventory) ÷ 2

Use case: A fashion brand with turnover of 8 means it sold through its full line eight times last year. This is a healthy number for trend-driven goods. 👚

18. Just-in-Case Inventory

Extra stock you hold to prevent stockouts during unexpected spikes in demand or supply delays. Think of it as a "buffer," or insurance for availability.

Use case: A toy company orders 20% extra before holiday season to avoid sell-outs when demand overshoots forecasts.

19. Just-in-Time (JIT)

Ordering items only as you need them to minimize storage costs. Works best with reliable suppliers, short lead times, and stable demand. Often means smaller, more frequent deliveries and close coordination with vendors.

Risk: Even small delays can cause stockouts.

Use case: An auto parts manufacturer receives brake pads daily from a nearby plant, cutting warehouse space by half while keeping assembly lines supplied.

20. Kanban

A visual scheduling system, often cards or digital signals, that triggers a reorder when stock hits a set level. Keeps ordering simple and prevents overstock without heavy forecasting.

Use case: A community clinic uses a two-bin Kanban for exam gloves. When the first bin empties, staff scan the card to reorder one bin’s worth.

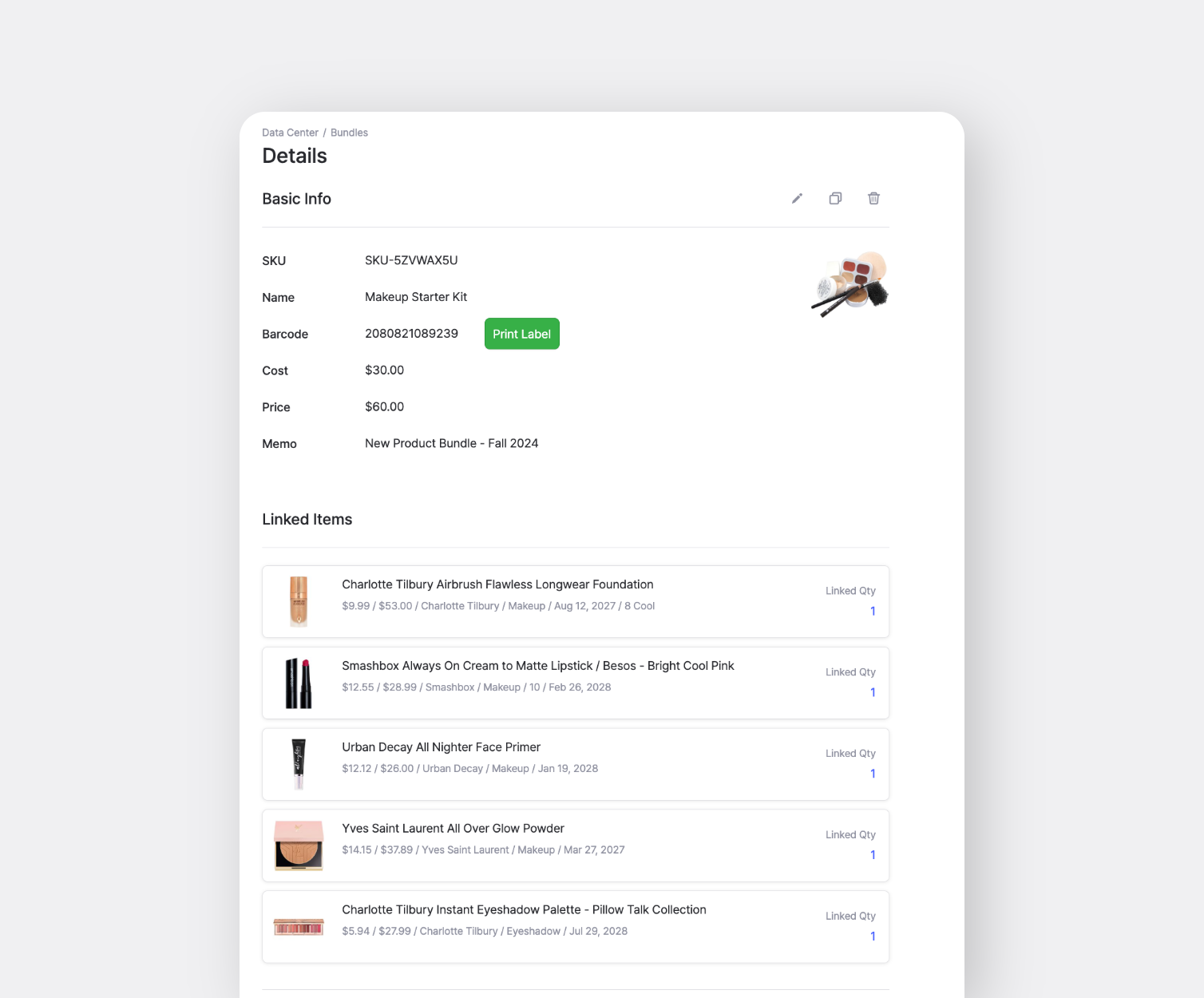

21. Kitting

Assembling multiple items into one sellable SKU to simplify selling and fulfillment.

How kitting works:

- Define the kit. Pick the items and quantities. Decide the purpose (gift set, starter pack, clearance).

- Create a kit code + parts list. Give the bundle a unique ID and write a short bill of materials with each component and its qty.

- Choose build method. Pre-build kits to ship faster, or assemble on demand to save space.

- Set price and margin. Add up component costs (include packaging), pick a target margin, and set the bundle price.

- Decide when stock reduces. Reduce component stock when you build the kit (treat it as a finished good) OR when the kit sells (virtual bundle).

- Package and pick. Label the kit, note any allowed substitutions, and add a quick QC check so the right items go in every time.

Use case: A cosmetics store bundles five items into a “Makeup Starter Kit” to move slow shades before the next season, create a giftable set, and automatically reduce counts for each component when the kit sells.

Example point: If the five items cost $30 total and the bundle price is $45.99, you clear shelf space and keep roughly a 26% gross margin.

22. Last-in, First-out (LIFO)

Using or selling the newest stock first. Often used for non-perishables or items that do not age or spoil.

Use case: Some hardware stores use LIFO on non-perishable fasteners so they always move the latest, plated batches.

Related: FIFO vs. LIFO: What's the Difference?

23. Lead Time

The time it takes from placing an order with a supplier to receiving the items in your warehouse. It tracks both average and variability, and can be used to set reorder points.

Use case: A gadget retailer sees 14-day lead times from overseas; they set reorder points at least two weeks before stock hits zero.

24. Lead Time Demand

The number of items you expect to sell or use during the lead time window.

Formula:

Lead Time Demand = Average demand per period × Lead time

Use case: If you sell 100 units per week and have a two-week lead time, your lead time demand is 200 units. Your reorder point should cover that, plus safety stock.

25. Lot Tracking

Monitoring a subset of items made or received together to manage recalls and quality checks more precisely. Similar to batch tracking, it tracks a specific production run, but is often used in food and pharma.

What to capture:

• Supplier

• Manufacture date

• Expiration

• Storage location

Use case: A vitamin maker recalls only Lot #V2025-07 instead of pulling all inventory from the shelves.

26. Min-Max Replenishment

A simple rule for reordering. You set a "Min" (the trigger level) and a "Max" (the target level). When available stock drops to Min or below, you order enough to bring it back up to Max.

- Min ≈ Lead time demand + Safety stock

- Max ≈ Min + Order-cycle demand

Use case

A hardware shop uses Min–Max for fasteners with steady demand. Staff check levels every Monday, and the system suggests the order to top each SKU back to Max. This keeps bins full without daily forecasting.

27. Minimum Order Quantity (MOQ)

The smallest number of items a supplier will accept in a single order. It affects cash flow, storage, and how fast you can test new items.

Use case: A T-shirt printer requires MOQ of 200; you plan designs and sales campaigns around that baseline and use presales to hit the first batch.

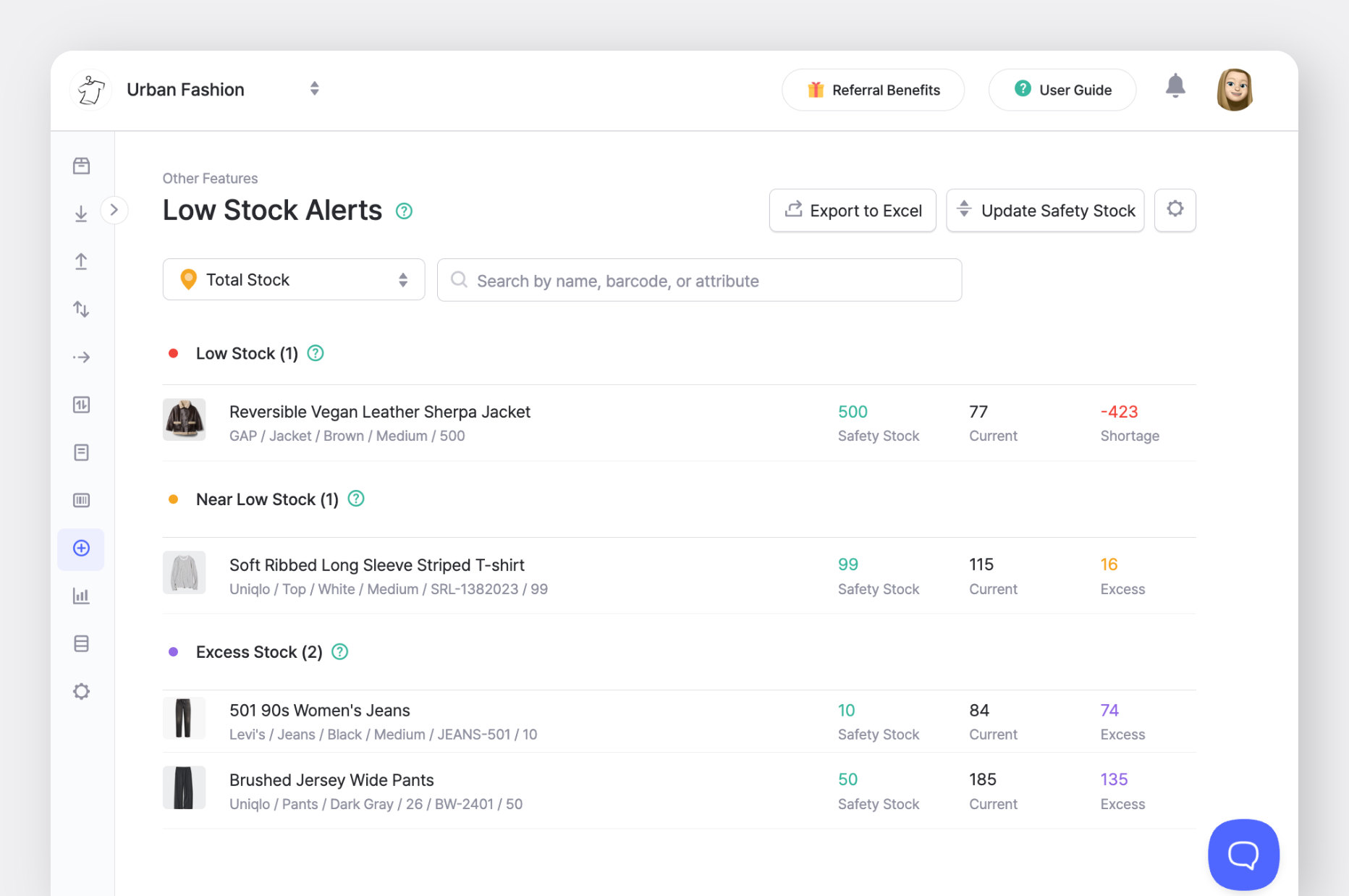

28. Overstock

Excess items beyond what you can realistically sell in a reasonable time frame. It ties up cash and raises carrying costs.

Use case: After a design change, a clothing brand finds three pallets of last season’s jackets: overstock tied up $30,000.

29. Par Level

A predefined minimum quantity of an item you want on hand. When stock falls below this, it’s time to reorder.

Simple rule: Order quantity = Par level − On-hand

Use case: A dental office sets par levels of mouthwash at 10 bottles; when they dip to nine, an automatic order goes to the supplier.

30. Perpetual inventory

A real-time tracking system that updates stock counts immediately after each transaction.

Use case: A pharmacy uses a scanner at checkout so front-counter and back-stock levels always match in real time.

31. Pick-and-Pack

The process of selecting items (picking) and preparing them for shipment (packing).

Use case: An online bookstore batches orders by aisle, then sends each cart to packing stations with printed pack slips. Throughput doubles with fewer errors.

32. Pick List

A print or digital list showing which items and quantities to pick from stock for each order.

What to include:

• Item name

• Bin location

• Quantity

• Order ID

• Due time

Use case: A florist’s pick list shows 12 roses, 6 lilies, and 3 ferns for each arrangement. It reduces substitutions, speeds assembly, and cuts remake costs.

33. Procurement

The end-to-end process of sourcing, negotiating, and purchasing your items.

Use case: A restaurant’s procurement team compares three fish suppliers on price, quality, and delivery times before signing a quarterly contract.

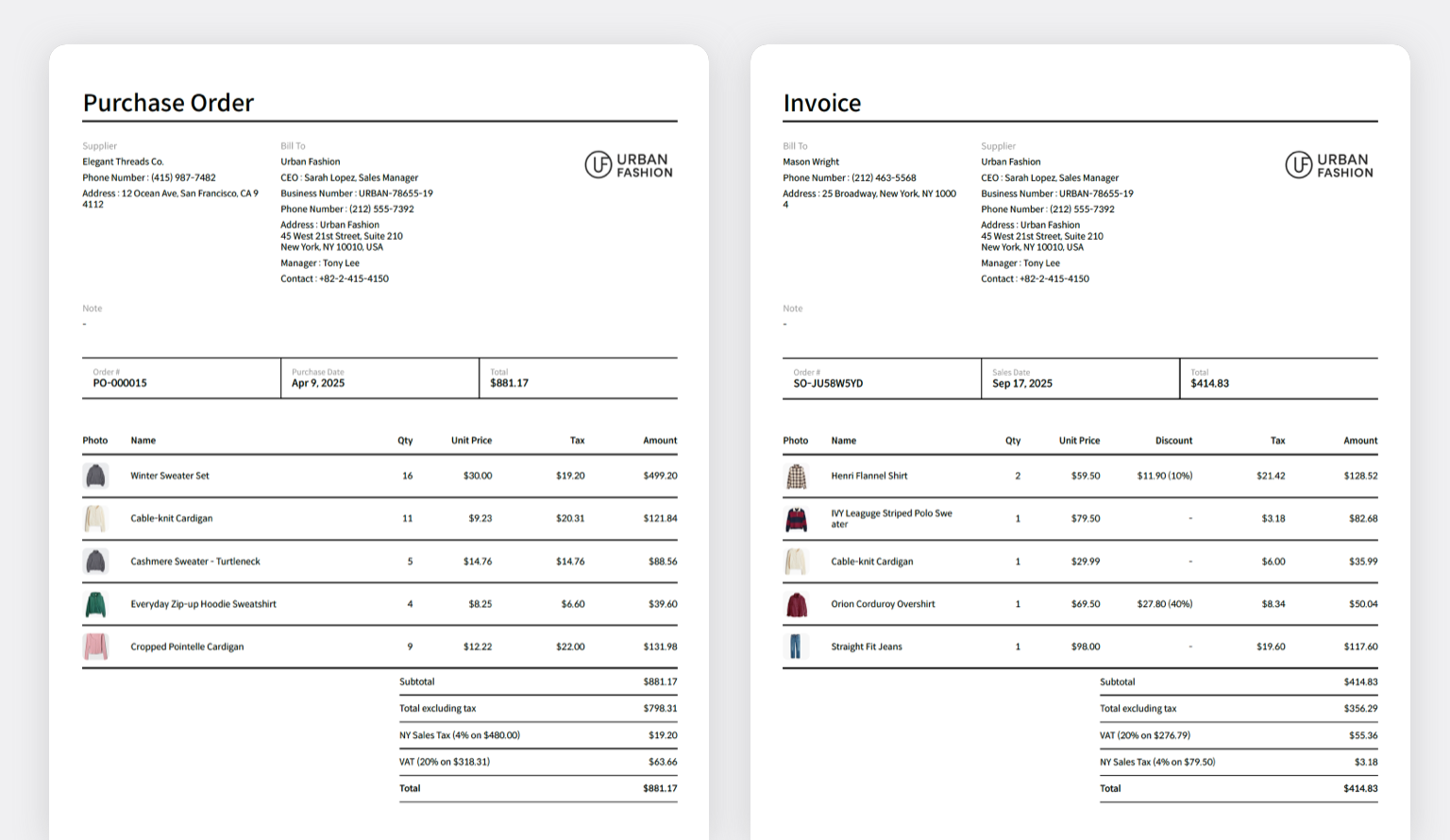

34. Purchase Order (PO)

A formal document sent to a supplier detailing items, quantities, agreed prices, and delivery dates. Serves as the basis for receiving and invoicing.

Use case: A craft brewery issues a PO for hops to lock price and reserve a lot for next month’s brew schedule, protecting against market swings. 🍺

Q – Z

35. Radio Frequency Identification (RFID)

Wireless tags that use radio waves to automatically track items. They're read by scanners without line of sight; great for fast cycle counts and finding misplaced items.

Use case: A fashion retailer drops RFID tags into purses; at shift change, employees scan entire racks in seconds instead of counting one by one.

Related: Barcode or RFID: Which One Should I Choose?

36. Reorder Point

The stock level at which you trigger a new order, based on lead time and demand forecasts.

Formula:

Reorder Point = Lead time demand + Safety stock

Use case: A toy distributor sets reorder points so popular drones never dip below 50 units. They factor two weeks of demand plus a small buffer.

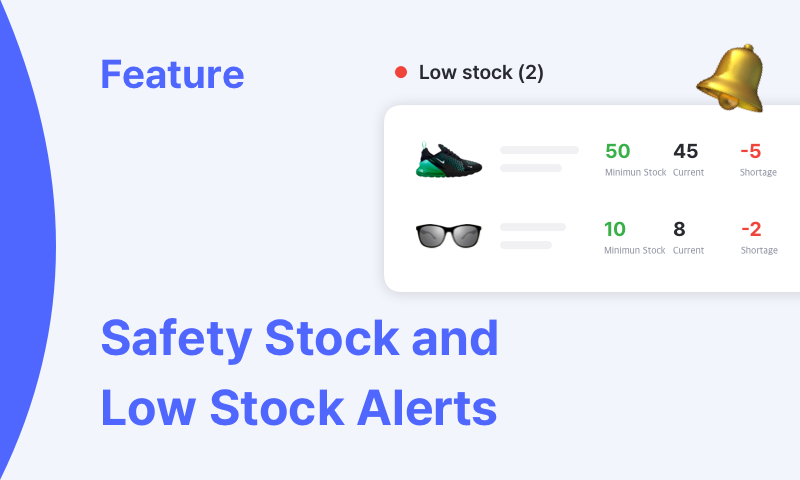

37. Safety Stock

Extra units held to cover unexpected demand or supply delays. This is your buffer against stockouts.

Use case: A gadget store keeps 10% safety stock on flagship smart speakers before a big product launch.

38. Sales Order (SO)

The request from a customer that initiates the picking, packing, and shipping process.

Use case: When Amazon logs a toy order, it immediately prints a sales order for the warehouse team.

39. Shrinkage

The loss of items due to theft, damage, or administrative errors, shown as a percentage of total stock.

Use case: A gourmet grocer audits monthly and sees 1.5% shrinkage. They install cameras and retrains staff, cutting it to 0.8%.

40. SKU (Stock Keeping Unit)

A unique code (usually alphanumeric) assigned to each distinct item configuration for tracking.

SKU vs. Barcode:

- SKU = your internal identifier.

- Barcode (like UPC/EAN) = a machine-readable code, often shared across retailers for the same item.

You’ll scan a barcode, but you manage and report by SKU.

Use case: A furniture store uses separate SKUs for size, color, and style. That way, “Gray Armchair” isn’t confused with “Black Armchair.”

41. Stock Audit

A formal review of inventory records and physical counts.

Use case: A luxury watch retailer closes one afternoon a quarter to count every display case and back-office safe.

42. Stock Valuation

The method you use to calculate the value of your on-hand items (FIFO, LIFO, weighted average, etc.).

Use case: A boutique uses weighted average cost so price swings in raw materials smooth out its profit reports.

43. Stockout

When you run out of stock for an item and can’t fulfill orders.

Use case: An outdoor gear store ran out of tents mid-July and lost $5,000 in sales plus repeat-customer goodwill.

44. Supply Chain

The network of suppliers, manufacturers, transporters, and warehouses that moves an item from raw materials to your customer.

What it includes:

Raw materials → Component suppliers → Manufacturer/Assembler → Regional distribution center → Store/Online → Customer → Returns

Use case: IKEA designs items to flat-pack, which cuts shipping volume and warehouse space. It uses long-term supplier relationships and regional distribution centers so stores can restock quickly while keeping transport costs low.

45. Throughput

The rate at which items move through your system—from receiving to shipping. It’s simply how many units you complete per time period.

Formula

Throughput = Units completed ÷ Time (e.g., orders per hour)

Use case: After reorganizing its floor, a snack subscription box operator increased throughput from 1,000 to 1,600 boxes per day.

46. Vendor-managed Inventory (VMI)

A arrangement where your supplier monitors your stock levels and replenishes items as needed.

- Pros: Fewer stockouts on staple items, less time spent creating POs, and vendor expertise on mix, facings, and seasonality

- Cons: Less direct control of order quantity and timing, risk of overstock

Use case: A small grocer lets its dairy supplier top off milk daily, freeing staff to focus on customer service.

Related: Vendor Managed Inventory 101

47. Warehouse Management System (WMS)

Software that controls and optimizes bin assignments, picking routes, and inventory locations.

Use case: After installing a WMS, a parts distributor cut picking errors by 40% and reduced aisle travel time by 30%.

48. Weighted Average Cost (WAC)

An inventory valuation method that averages the cost of all units available during a period. This approach smoothes price swings across purchases.

Use case: A chemical supplier uses weighted average when prices swing daily so invoices stay stable.

49. Work-in-Process (WIP)

Items that are partway through production or assembly, not yet ready for sale.

Use case: An electronics assembler tracks WIP on circuit boards to balance workloads and prevent bottlenecks.

50. Zero Inventory

An extreme JIT approach where you keep no items on hand, relying on dropshipping or instant replenishment. You focus on marketing and order flow; partners make and ship.

When it works:

- Custom or made-to-order items (e.g., print-on-demand apparel)

- Large or long-tail catalogs where holding stock isn’t practical

- Early testing of new items when cash is tight

Use case: A custom-print mug seller uses zero inventory. Each order prints on demand at the supplier’s facility.

How to Use This Glossary

- Share it with your team so everyone speaks the same language.

- Bookmark key terms that match your business model (e.g., JIT vs. just-in-case).

- Review quarterly to keep pace with new strategies and tools.

For related concepts, see our "Small Business Glossary of Terms." You can also add this glossary to onboarding so new hires ramp faster.

With these definitions, you’ll make more informed choices about how to order, store, and sell your items. If there’s a term you want us to add, let us know!

📧 Contact us: support@boxhero.io