How to Receive New Stock Without Creating a Mess: A Step-by-Step Guide

When a supplier delivery shows up at your warehouse, backroom, or front desk, it rarely arrives at the “perfect” time. Maybe you’re in the middle of a customer order. Maybe half your team is out. Or maybe the person who placed the order isn’t the one receiving it.

This is exactly when inventory mistakes happen—and they don’t usually show up until much later, when you go to pick, sell, or reorder that item.

Inaccurate stock levels, missing batch records, and wrong pricing usually trace back to a single moment: the day you received the item.

From our experience supporting teams across retail, logistics, manufacturing, and distribution, here’s what separates clean, accurate stockrooms from ones that are constantly off by a few units.

Step 1: Don’t Move a Single Box Until It’s Verified

As tempting as it is to just get the boxes out of the way, moving stock before verifying it is one of the most common causes of lost inventory.

Before touching anything:

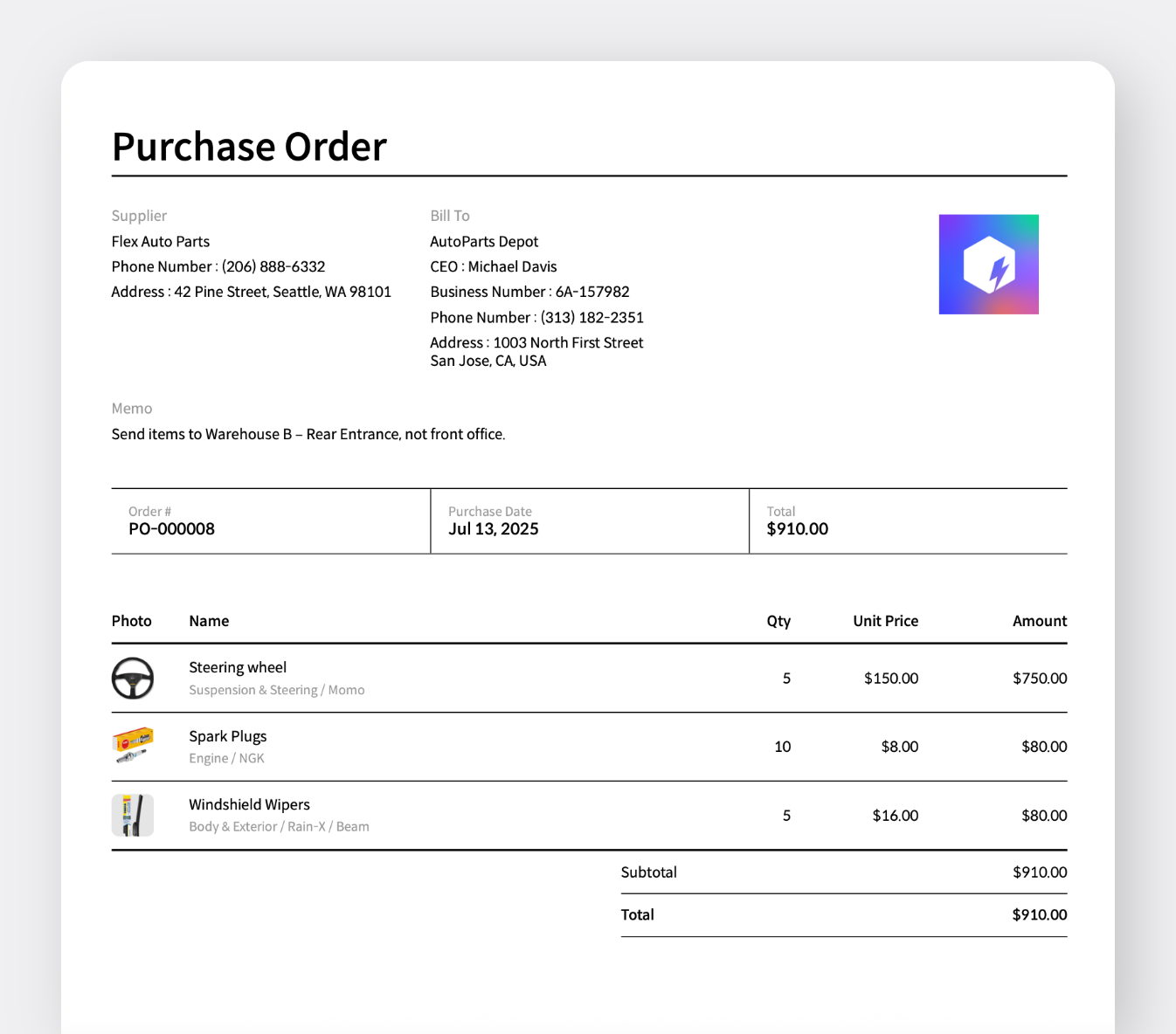

- Match the shipment to the original PO. Don’t rely on memory or assumptions. Pull up the purchase order and cross-check item names, quantities, and units of measure.

- Check for substitutions. Sometimes suppliers make swaps (e.g. different packaging size or brand variant) without notifying you.

- Inspect for damage or signs of repackaging. Especially if you’re tracking by batch or expiration, any tampering can affect whether you accept or reject the goods.

You don’t want to record or update anything in your inventory system until you know what actually arrived. Make sure to cross-check the supplier’s packing list with your original order.

Step 2: Use a Consistent Receiving Method

Too many teams rely on a paper slip, Excel note, or someone’s memory to record what came in. It works—until that person goes on vacation or forgets to follow up.

"Any errors at this stage [receiving] can cascade through the entire supply chain, leading to a multitude of issues such as stockouts, overstocking, and inaccurate records, which in turn can affect sales, customer satisfaction, and financial reporting." – FasterCapital

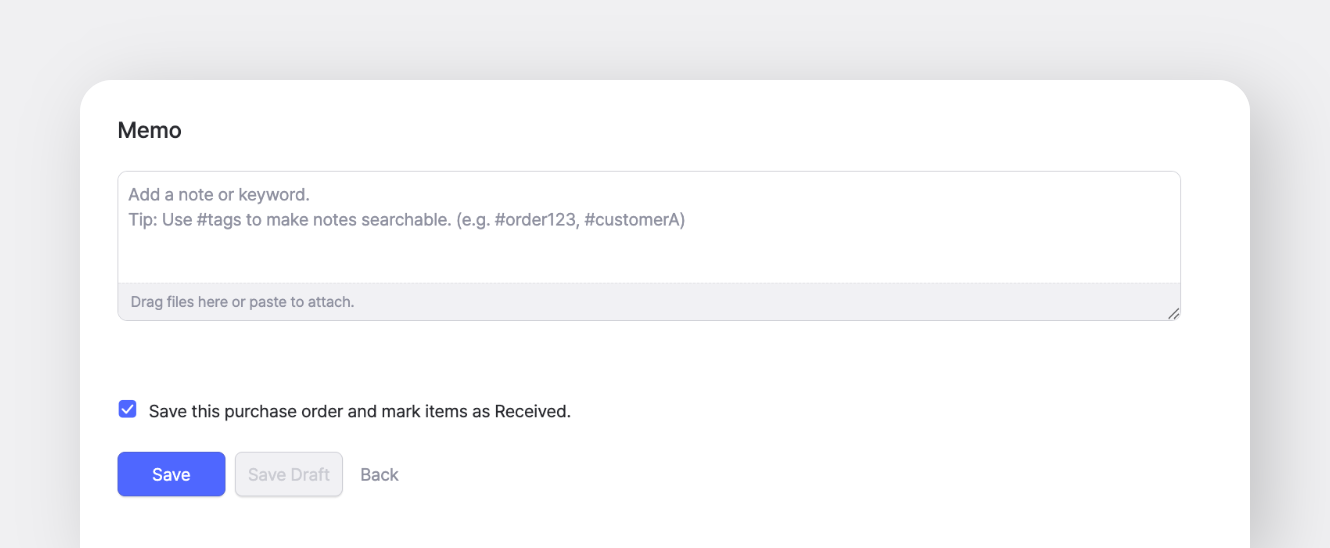

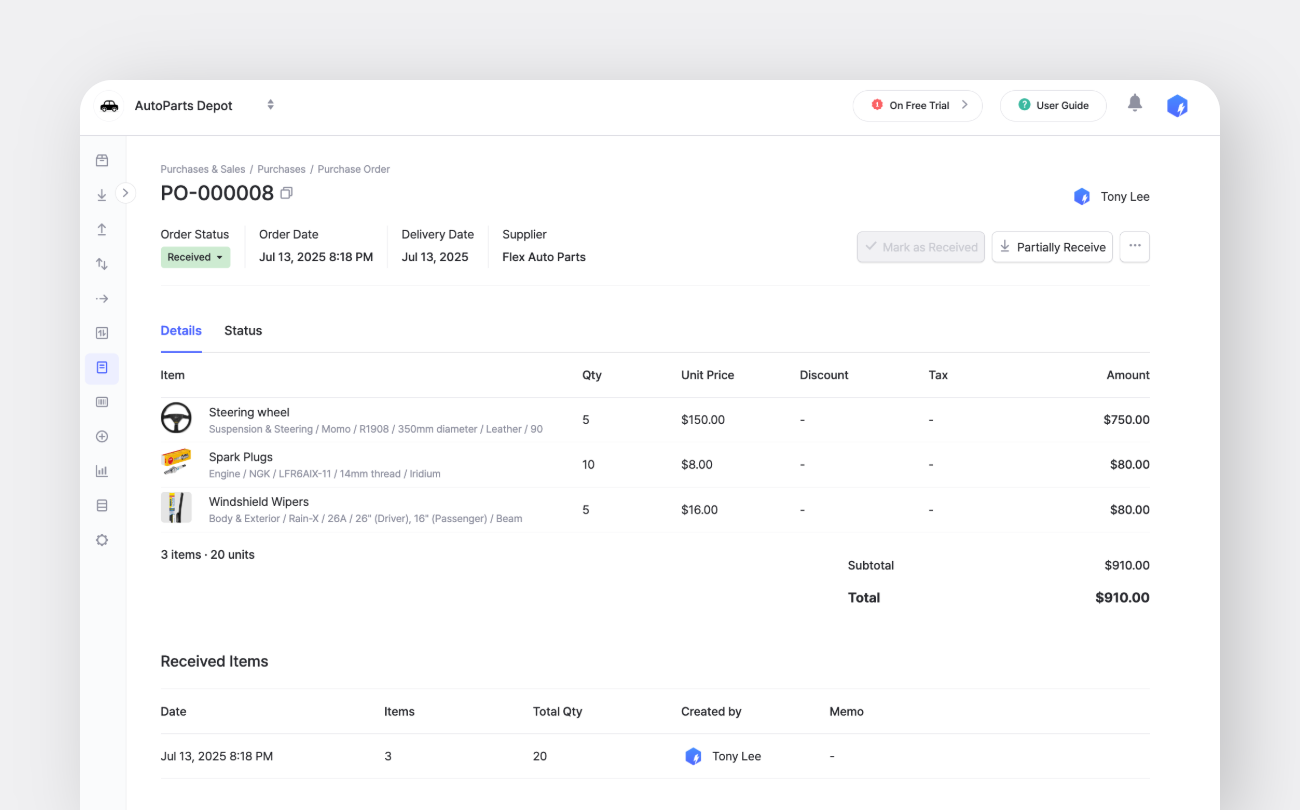

With BoxHero, the receiving process is built directly into the Purchase Order screen:

- Select the ordered items and enter the quantity received.

- Check the box labeled "Save this purchase order and mark items as Received."

- Optionally enter a note or keyword (e.g.

#order12345,#urgent,#damaged) in the memo field to make the entry searchable. - Attach a file if needed—for example, the supplier invoice or delivery slip.

- Click the “Save” button to complete the receipt.

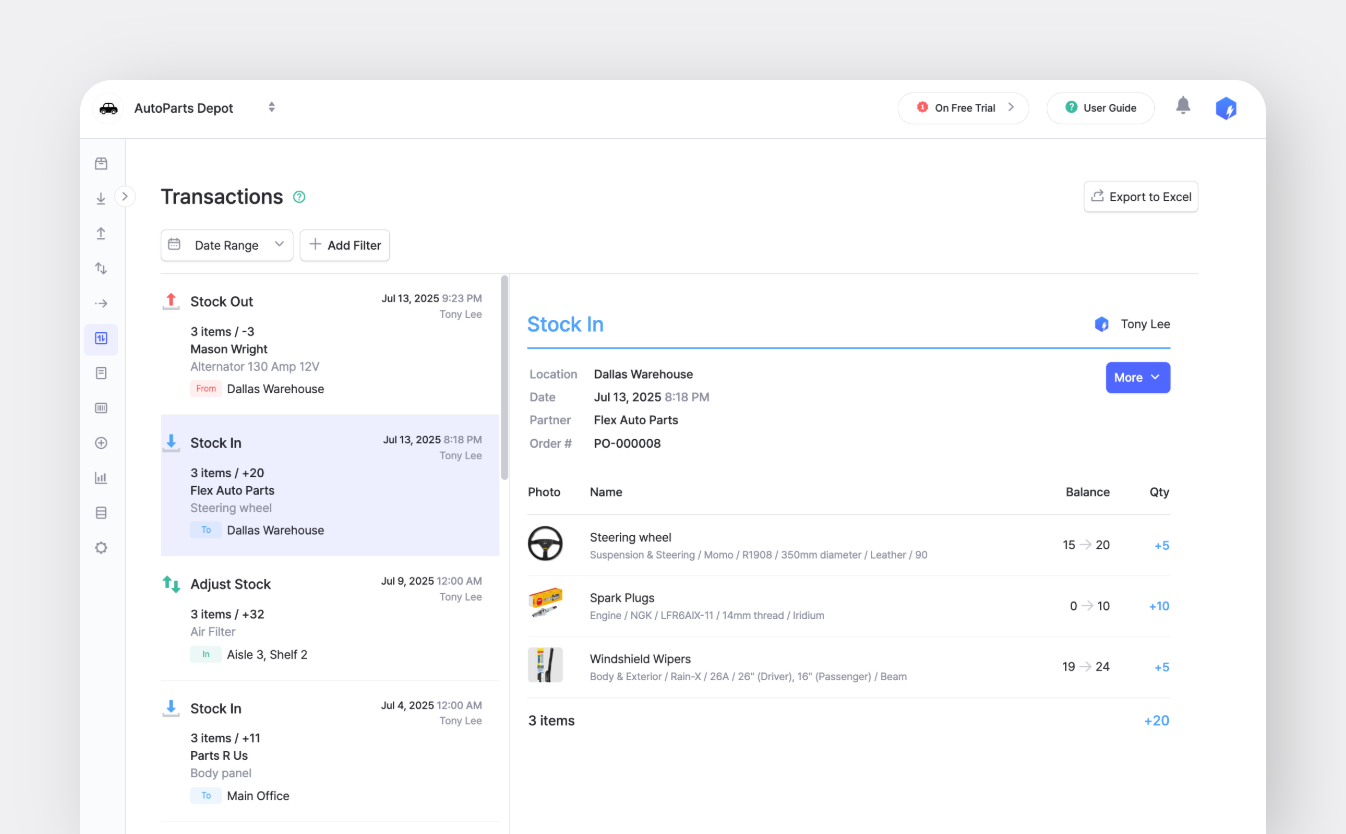

Every stock movement is logged in real-time and tied to the item's transaction history. It's perfect for small teams with rotating responsibilities; anyone can check when, why, and by whom something was received.

Step 3: Update Purchase Price (Yes, Every Time)

A common blind spot: the team receives inventory but doesn’t update the new unit cost. Over time, this leads to inaccurate margins and bad pricing decisions.

When you receive stock in BoxHero:

- Tap into the Unit Price field

- Record the price actually paid on the latest invoice.

- Optionally enter any taxes or discounts, if relevant

Sometimes suppliers change pricing without much notice. Make sure the price you paid matches the last recorded price. It'll help with margin tracking, supplier negotiations, and reorder decisions later down the road.

Step 4: Add Expiration or Production Dates

For items with a shelf life—like food, cosmetics, or medical supplies—recording key dates at the time of receipt helps you stay ahead of stock rotation.

In BoxHero, you can add custom attributes like:

Expiration DateManufacturing DateBest Before

Some teams also include the expiration date in the item name or memo field (e.g. N95 Mask – Exp 2025-12-01) to make it easier to spot during picking or stock checks.

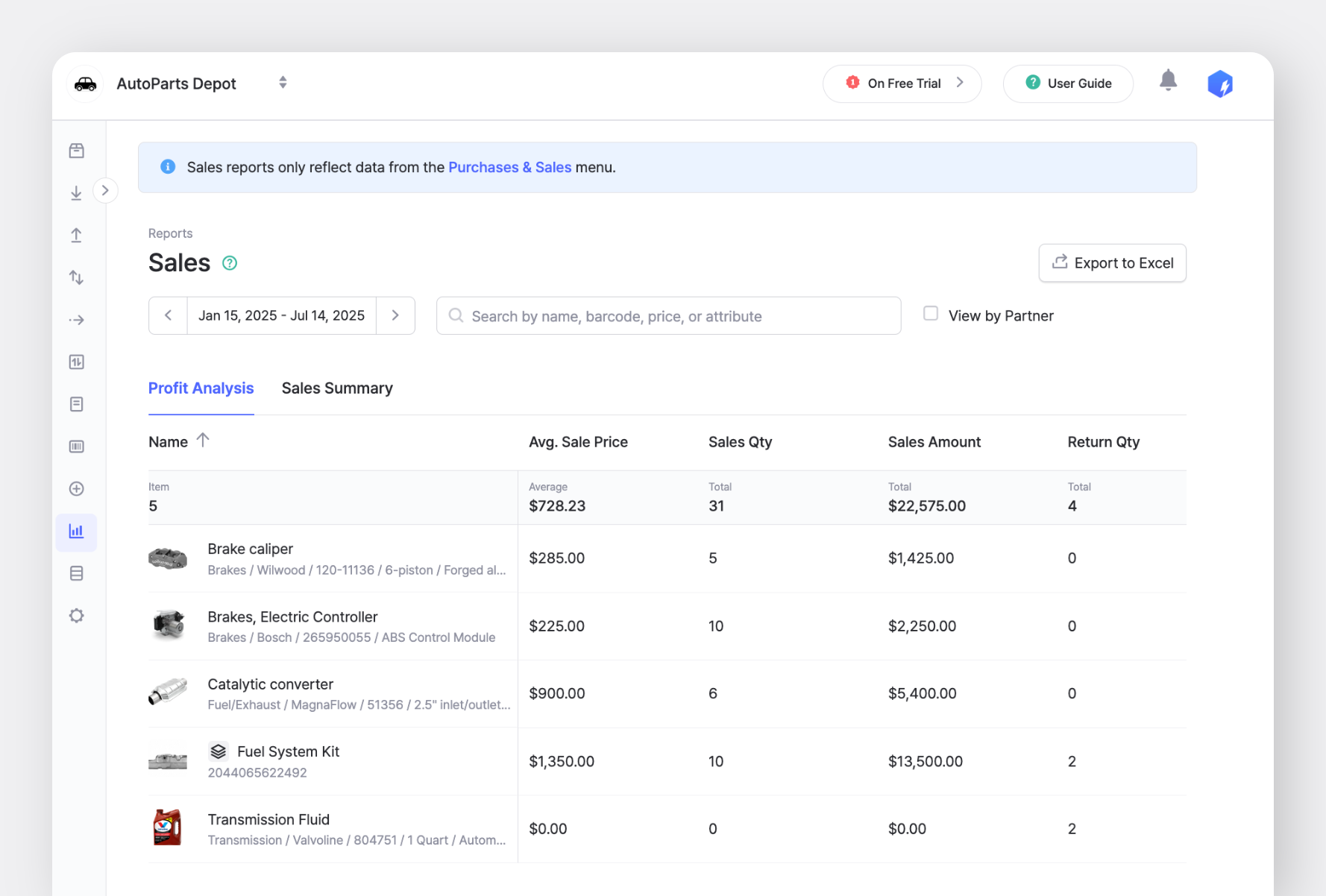

Step 5: Always Confirm Final Stock Count

It’s not enough to hit “Receive” and walk away. At least once a day (or after a large delivery), open the item in BoxHero and double-check:

- Does the on-hand quantity reflect what you now have in storage?

- Does the item's transaction history match your physical receipt?

Mistakes tend to happen when multiple people are updating stock at once—or if the same shipment is received twice by accident. Make sure to confirm the new stock quantity includes what you just received.

Industry best practices highlight that cycle counts (i.e. daily checks on subsets of inventory) are key for continuous accuracy and root-cause identification.

6. Photograph the Delivery or Invoice

Lost paperwork is a universal problem. If you ever find yourself saying, “I’m pretty sure that came in last week, but I can’t find the invoice,” start snapping photos.

- Take a photo of the delivery slip, invoice, or box label

- Attach it to the item’s memo section in BoxHero

Even if you clean it up later, you’ll have a traceable record while the details are still fresh. It's a great backup!

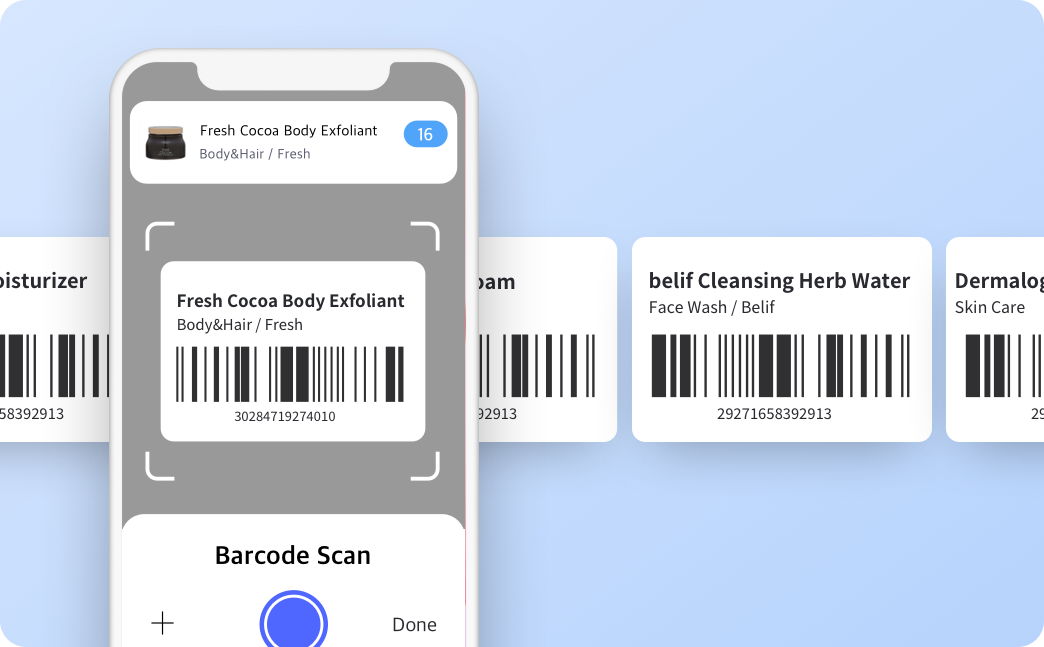

Optional: Use Barcodes or Scan Receipts

If you're using barcodes, scan items upon arrival to instantly pull them up in BoxHero. You can receive stock faster without manual searching.

Final Advice: Make Receiving a Team Habit

Even the best inventory system can’t fix inconsistent receiving habits. It only works if everyone who interacts with new stock knows what to do, follows the same steps, and updates the system immediately.

- If you’re a team of one, build the habit early.

- If you’re a team of many, document the process once and review it with new staff.

Small changes (like updating price on receipt or photographing invoices) make a big difference down the line.

And the good news? BoxHero makes it easy to stay consistent, no matter who’s doing the receiving.