How to Optimize Your Warehouse Logistics

Organizing a warehouse isn't just about neatly arranging your items. The purpose of warehouse organization is to improve the flow of logistics operations and increase work efficiency. If you're still unsure about how to organize a warehouse properly, keep reading to follow our warehouse organization tips!

Why Warehouse Organization is Important

Employees who work in a well-organized warehouse can find the items needed for logistics operations quickly and efficiently. The process of receiving, storing, and transferring products is optimized, which means less time spent on logistics, and in turn, more time to focus on identifying products with low stock (stockouts) or excess inventory (overstock).

In addition, proper organization prevents warehouse picking errors of products that look similar and are easily confused. Poorly organized warehouses could lead to employees making more mistakes and causing products to be misdelivered.

Strategically organizing your warehouse can create more space while you hold the same amount of inventory. In fact, effective organization allows you to consolidate items that were previously stored in two separate warehouses into one. This means reduced costs associated with the building for operating the warehouse, including rent, interest, insurance, maintenance, heating and cooling, and even taxes.

Moreover, a well-organized warehouse can prevent items from getting spoiled or damaged. Inventory that can no longer be sold to customers due to spoilage or damage will result in sunk costs, which means the expense cannot be recovered. As a business owner, there's nothing worse than paying to dispose of these unusable inventory. If you're carrying obsolete inventory despite maintaining appropriate stock levels, it's time for you to reassess your warehouse organization practices.

4 Tips for Efficient Warehouse Organization

1. Layout Design

"Layout" refers to the effective arrangement of different components. Warehouse organization begins with a layout design, which involves figuring out how to use the limited space in the most efficient manner.

To start, you'll need a floor plan of the warehouse, which is a top-down view of the space. With a floor plan, it’ll be easier to position racks and other equipment to create optimized workflows.

After deciding on the direction of the workflow, it's time to arrange the racks in straight lines, L-shapes, or U-shapes to minimize the time and effort required for operating the warehouse. Make sure to avoid creating a workflow that requires employees to backtrack.

It's also important to place high-turnover products near the exit for easy access to shipping. And don't forget to leave plenty of space in the aisles so that employees can move around safely!

2. The 5S Methodology

5S is a set of guidelines for warehouse employees that help create a more organized and productive workspace. Originating from Japan, it is a management technique that groups five behavioral "pillars" that stem from the following Japanese terms:

• Set in Order (Seiton): Store necessary items in designated locations and maintain the required quantities.

• Shine (Seiso): Keep the work environment clean and sanitary to ensure a pleasant working environment.

• Standardize (Seiketsu): Create and implement standards for maintaining the previous steps.

• Sustain (Shitsuke): Maintain the correct procedures and adhere to management guidelines for productivity.

Employees who adopt the 5S methodology spend less time searching for necessary items. If you're struggling with warehouse management, try to incorporate sorting, setting in order, shining, and standardizing into your daily operations and sustaining these practices in the long term.

3. Labeling

"Labels" are tools that communicate the meaning of each space to employees. Basically, you're naming shelves and racks so that your team can quickly identify where items are stored (based on the labels).

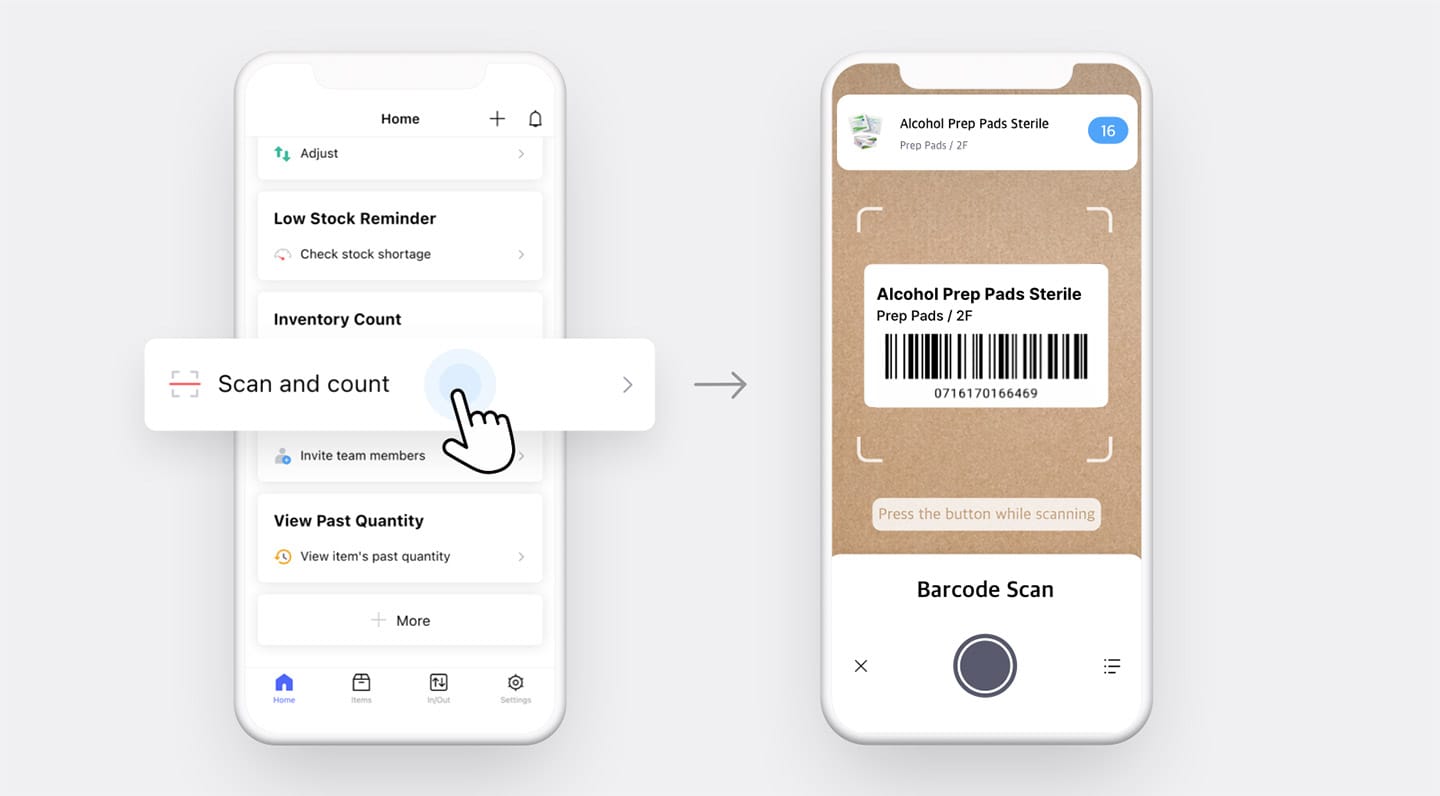

Start by numbering the racks based on your designed warehouse layout. You could also use different colors for labels based on the type of product being stored. This allows you to distinguish between the different spaces without having to read the contents of the label. It's also a good idea to include labels with barcodes on each shelf where products are stored. Barcodes contain product information that enhances warehouse management efficiency even further.

Even if you're not a paid user, you can still use BoxHero's free online barcode label printing service. No need to sign up or install any software. And yes, it's completely free!

Once the labels have been attached, we recommend checking them periodically by inspecting the racks and shelves. If labels for products that are no longer sold or have been moved to different locations are still attached, it can lead to confusion.

4. Inventory Count

Inadequate warehouse management is one of the many factors leading to discrepancies between computerized inventory and physical stock quantities. Products may not be counted if they're not being stored in the designated location, or may even be damaged due to improper storage methods. Inventory counts serve as a means to maintain inventory accuracy, but are also a way to check for any gaps in warehouse management practices.

Knowing and implementing effective warehouse organization methods will naturally help to improve inventory management. BoxHero's Blog provides various insights and tips tailored for companies managing inventory.

Click any of the links below to find valuable information that can help you manage your inventory more efficiently!

▶︎ Inventory Management Best Practices for Small Business Growth

▶︎ Growing Your B2B Wholesale Business

▶︎ What is Reverse Logistics?